Infographic Page

Newly Developed Products 2016 - Part 1

With 2017 on the horizon, it is the perfect time to reflect on what our most outstanding accomplishments were this past year. Here are some of the breakthrough epoxies, silicones and UV curable products that were developed in 2016 at a glance.

Featured Products

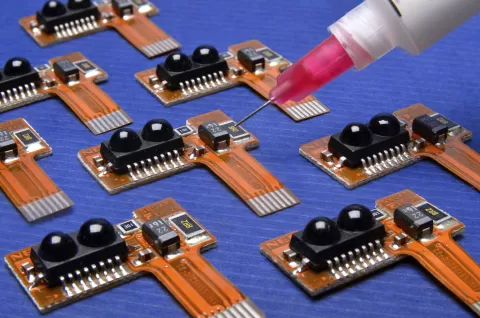

Image

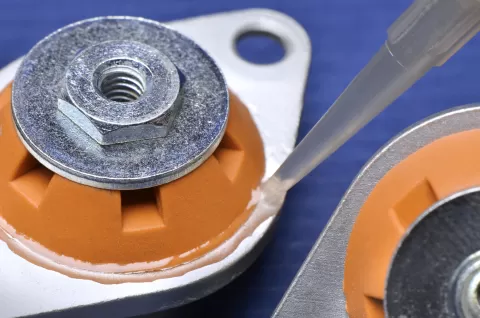

single component epoxy adhesive features unmatched heat transfer properties. Capable of being applied in bond lines as thin as 10-15 microns. Low coefficient of thermal expansion. Meets NASA low outgassing specifications. Low shrinkage upon curing Operating temperature is 4k to +400°F.

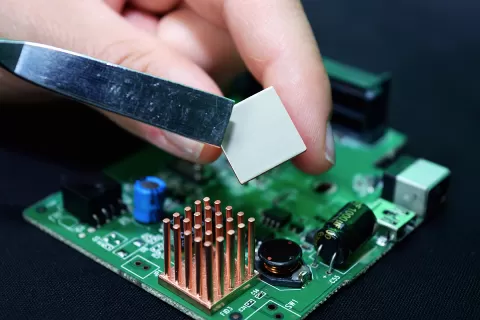

Image

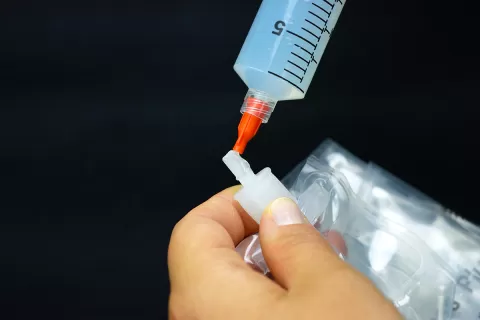

One component epoxy for bonding and underfill applications. Thermally conductive/electrically insulative. Meets NASA low outgassing specifications. High mechanical strength properties. Ultra fine particle sizes lowers thermal resistance. Convenient processing at moderate temperatures. Serviceable from -60°F to +250°F.

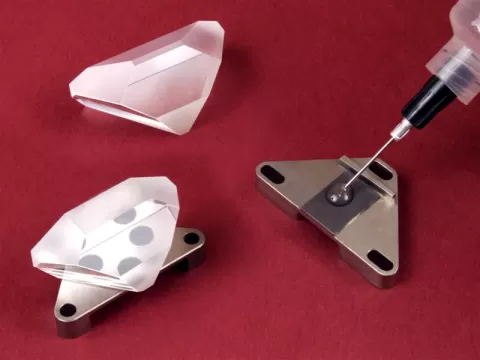

Image

Two component nanosilica filled epoxy for potting, coating and sealing. Optically clear. Low shrinkage. Superior electrical insulation properties. Toughened system. Successfully tested for 1,000 hours 85°C/85% RH. Serviceable from -100°F to +450°F.

Image

Acetoxy type system. Bonding, sealing, coating compound. Pass USP Class VI testing and ISO cytotoxicity specifications. Tack free time 10-20 minutes at 75°F. Shore A hardness 20-30. Elongation 400-600%. Paste viscosity. Service temperature range -75°F to +400°F.

Image

Thermally conductive/electrically insulative epoxy for large potting/encapsulation applications. Low exotherm. Long working life. Excellent flow properties. Very low shrinkage upon cure. Impressive compressive strength. Shore D hardness 80-90. Serviceable from -60°F to +250°F.