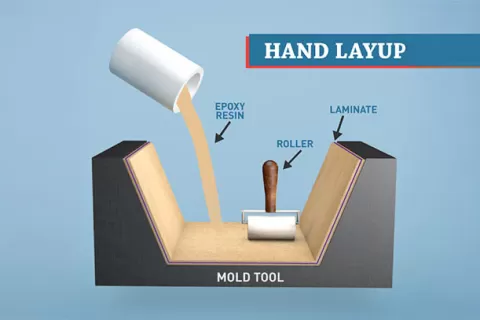

Wet Lay-up/Hand Lay-up Manufacturing Process for Composites

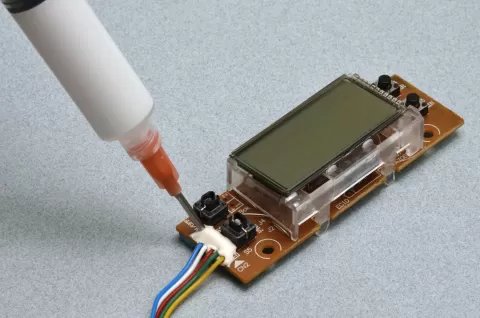

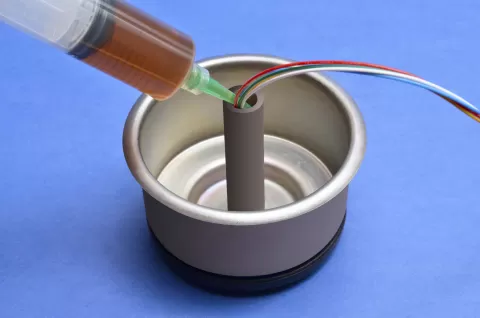

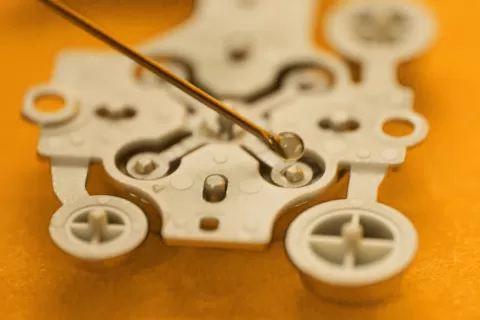

The wet lay-up or hand lay-up process is an open-mold fabrication method used to create composite parts. Layers of reinforced laminations are manually positioned with an epoxy resin system using brushes or rollers until the desired shape and thickness are achieved, ensuring a high-quality finished composite.

Advantages of Wet Lay-up

- Versatility: It is suitable for a wide variety of composite shapes, from simple panels to complex, large-scale structures.

- Broad Material Compatibility: It can be used with a wide range of fabric layers, including plain, twill, and plain basket weaves, whereby these are stitched bonded fabric layers are impregnated with an appropriate epoxy resin system.

Enhancing Quality with Vacuum Bagging

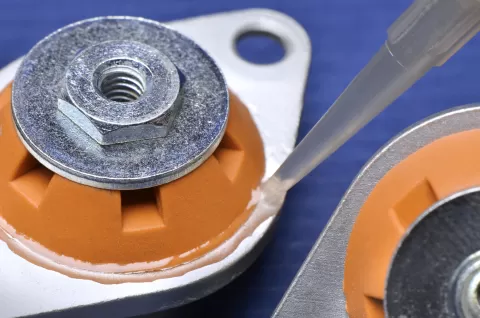

To prevent air entrapment and voids, which can compromise the strength and integrity of the composite, a vacuum bag can be placed over the wet lay-up. This technique applies uniform pressure, squeezing out excess resin and trapped air to ensure a solid, high-density part after the resin has polymerized. This simple step is critical for producing high-quality components that meet stringent performance requirements.

To enhance performance, composites can be cured at room temperature, in an oven, or in an autoclave. For heat-cured systems, a controlled temperature ramp is essential to prevent warping from uneven expansion. A secondary post-cure can also be used to further maximize the final properties of the composite.

The versatility and effectiveness of the wet lay-up process make it invaluable across numerous industries. Common applications include wind turbine blades, automobile and bus parts, aircraft components, structural panels, air handling equipment, and marine systems.

Most Popular Epoxy for Wet Lay-up and Hand Lay-up