EP110F8-1

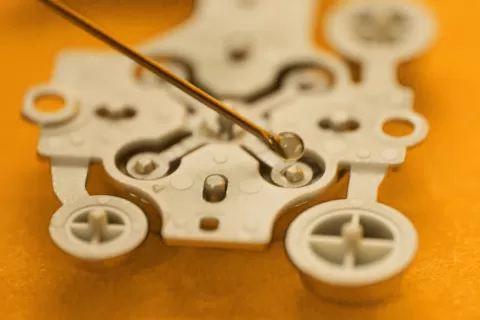

Two component, high performance epoxy for potting, sealing, encapsulating and casting

Key Features

- Exceptionally long working life at room temperature

- Low viscosity

- Outstanding electrical insulation properties

- Highly resistant to thermal cycling and shock

Typical Properties

Viscosity

2,500-5,000 cps

Cure Schedule

4-6 hours at 250-300°F

Hardness

65-75 Shore D

Service Temperature Range

-80°F to +325°F

Dielectric Constant

2.81

Elongation

85-95%

Bild

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863