Medical Adhesives, Sealants and Coatings

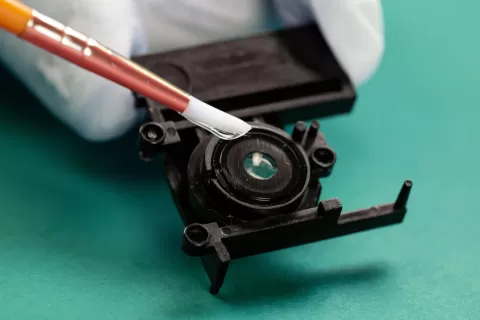

One and two component systems are designed to meet the needs of medical device manufacturers. These products offer high reliability and can withstand difficult conditions encountered in use. They cure at ambient or elevated temperatures or upon exposure to UV light. For more information on curing requirements, key properties, and service temperature ranges view these charts on biocompatible adhesives.

Learn more about our adhesive systems for the medical industry:

Dental Equipment

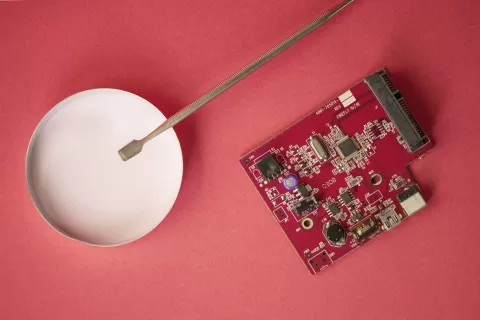

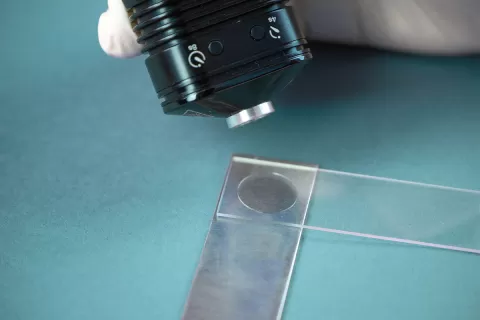

Diagnostic Equipment

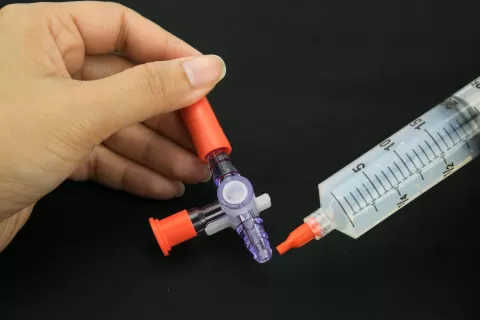

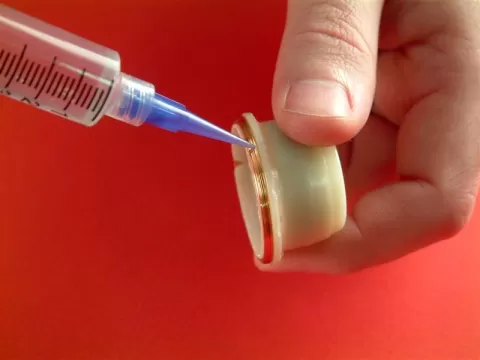

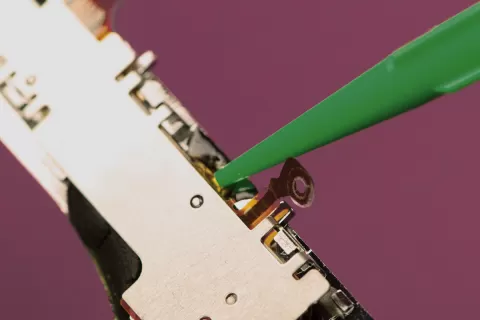

Disposable and Reusable Devices

Medical Electronics

Medical Monitoring Systems

Molecular Diagnostic Instruments

Orthopedic and Prosthetic Devices

Respiratory Devices

Surgical Instruments

Pandemic Preparedness

Key Benefits of Master Bond Medical Adhesive Systems

- Biocompatibility—USP Class VI approved

- Resistance to sterilization—select compounds resist autoclaving, radiation, ethylene oxide and cold sterilants

- High bond strength to similar and dissimilar substrates

- Solvent free

- Fast curing systems

- Gap filling

- Easily automated

- Optically clear formulations

- Available in a range of hardnesses

- Thermal stability

Special compounds can withstand multiple sterilization cycles. Additionally, highly elastic, medical grade products have been developed for stress relaxation and adhering flexible substrates that are typically hard to bond to with conventional medical grade adhesives.

Find out more about our full product line of USP Class VI approved adhesive systems.

Find out more about our products meeting ISO 10993-5 cytotoxicity requirement.

Some of Our Most Popular Medical Epoxy Adhesives

Latest Developments

Find the Right Adhesive for Your Application

With thousands of formulations, our expert engineers provide personalized guidance to ensure you select the ideal material for your specific needs.

Prefer to browse on your own first? Explore our Product Selector.