Biocompatible Adhesives

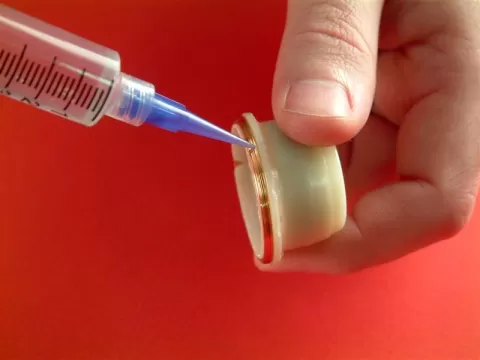

USP Class VI approved one and two component adhesives, sealants and coatings are formulated for the assembly of medical devices. These specialty compounds are designed to adhere to dissimilar substrates, resist exposure to sterilization and for easy application.

Key Advantages of Master Bond's Biocompatible Compounds

Medical grade adhesives, sealants, coatings and potting/encapsulation compounds need to be non-toxic and show compatibility with blood and body fluids. Additionally, they must be biologically inert. There are two standard tests used to determine their suitability: U.S. Pharmacopeia (USP) Class VI and/or ISO 10993. Master Bond offers biocompatible compounds, which meet one or both specifications.

General Comparison of Different Chemistries for Medical Device Adhesives

Overview: Epoxies and Silicones

| Epoxies | Silicones | |||

|---|---|---|---|---|

| 1-part | 2-part | 1-part | 2-part | |

| Applications | Bonding, coating, sealing and potting | Bonding, coating, sealing and potting | Bonding, coating, and sealing | Bonding, coating, sealing and potting |

| Typical Service Temperature Range | 4K to 400°F | 4K to 400°F | -75°F to 400°F | -65°F to 400°F |

| Curing Requirements | Fast cures at elevated temperatures | Room/heat curing systems | Room temperature (moisture) curing | Room/heat (addition) curing systems |

| Key Properties | Structural, with good temperature resistance and easy processing | Excellent chemical resistance, with very good physical strength profile | High degree of flexibility with no mixing needed | Excellent flexibility, and cures in thick sections with low stress imparted |

Overview: Other Chemistries

| UV/LED Curing Systems | Epoxy-Polyurethane Blends | Cyanoacrylates | |

|---|---|---|---|

| Applications | Bonding, coating, sealing and encapsulation | Bonding, coating, sealing and potting | Bonding, coating, and sealing |

| Typical Service Temperature Range | -60°F to 400°F | 4K to 250°F | -60°F to 250°F |

| Curing Requirements | Light curing systems (-365 nm to 405 nm) Dual curing with heat | Room/heat curing systems | Room temperature curing systems |

| Key Properties | Quick cure times, along with good optical as well as physical strength characteristics | Good degree of toughness, combining flexibility with good overall physical strength properties | Good bond strength capability with quick cures for smaller components |

Bond Strength

| Epoxies | Silicones | UV/LED Curing Systems | Epoxy-Polyurethane Blends | Cyanoacrylates | |

|---|---|---|---|---|---|

| Metals | Excellent | Good | Good | Good | Excellent |

| Plastics | Excellent | Fair | Very Good | Fair | Very Good |

| Glass | Very Good | Good | Very Good | Good | Very Good |

| Rubbers | Very Good | Fair | Fair | Good | Good |

Sterilization Resistance

| Epoxies | Silicones | UV/LED Curing Systems | Epoxy-Polyurethane Blends | Cyanoacrylates | |

|---|---|---|---|---|---|

| Repeated Autoclaving | Excellent | Poor | Very Good | Poor | Poor |

| Repeated Chemical Sterilization (Sterrad®) | Excellent | Poor | Very Good | Poor | Poor |

| Gamma, E-beam, EtO etc. | Excellent | Excellent | Excellent | Very Good | Good |

All systems can be applied manually, semi-automatically and automatically.

Sterrad® is a registered trademark of Johnson & Johnson.

Find out more about our full product line of USP Class VI approved adhesive systems.

Find out more about our products meeting ISO 10993-5 cytotoxicity requirement.

Most Popular USP Class VI Approved Products