Fuel Resistant Adhesives, Sealants & Coatings

Innovative compounds have been developed with enhanced chemical resistance properties. These products feature long term durability, high reliability and superior bond strength. Specific formulations offer rapid cures at ambient temperatures, elasticity, convenient mix ratios and easy brushable application. Master Bond's adhesives, sealants and coatings provide advanced protection against oil, ethanol and methanol exposure.

Bild

Industrial Applications Utilizing Master Bond's Fuel Resistant Adhesive Systems

- Aerospace

- Automotive

- Energy

- Chemical processing

- Off-highway vehicles

Chemical Resistance Data for Master Bond Formulations

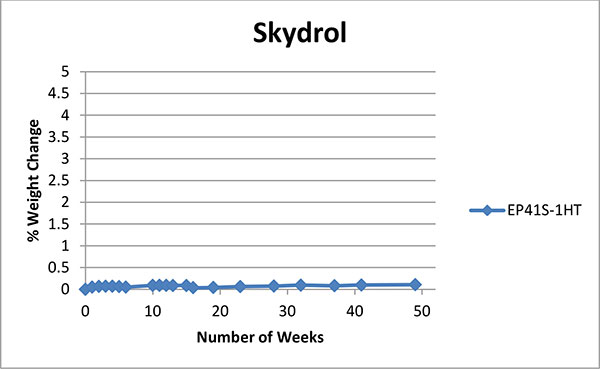

The graph below shows the weight change of EP41S-1HT as a % versus time (number of weeks) when immersed in skydrol:

Master Bond's database of chemical immersion tests extends up to 10 years

Most Popular Fuel Resistant Adhesives, Sealants & Coatings

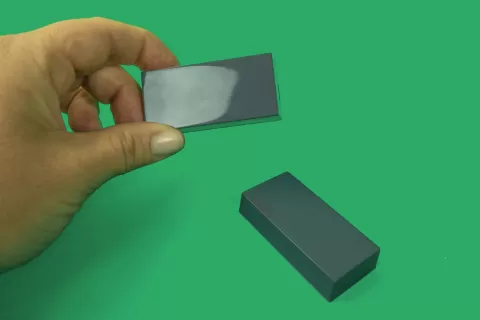

Bild

Easily processable, two part epoxy with excellent chemical resistance, particularly to solvents. Available in black. 100% reactive. Low viscosity. Ambient temperature cure. Service temperature range from -60°F to +300°F.

Bild

Two component polysulfide/epoxy adhesive/sealant. Cures at room or elevated temperature. Exceptional toughness and chemical resistance properties. Withstands exposure to fuels, oils, hydrocarbons and hydraulic fluids. Forgiving one to one mix ratio. Excellent electrical insulation properties. Serviceable from -80°F to +250°F.

Bild

Non-drip epoxy paste has outstanding temperature and chemical resistance. Superior toughness and thermal cycling capability. Meets low outgassing specifications. Withstands 1,000 hours 85°C/85% RH. Superb electrical insulator. Service temperature range -80°F to +450°F.