Pultrusion

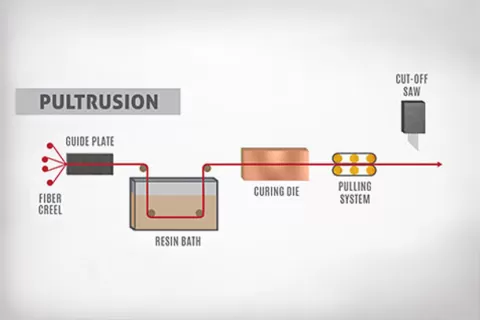

Poltrusion is a continuous, fast, economical process for manufacturing composite parts. Racks or creels of spools of reinforced fibers--such as glass, carbon, aramid--are impregnated or wetted-out with low viscosity epoxy resin and pulled through a heated die.

Key Advantages and Properties of Pultruded Parts

This die serves two critical functions: it shapes the composite to its final desired cross-section, and the elevated temperature within the die triggers the polymerization of the epoxy resin. This process ensures that the resin content is precisely controlled. Once the composite exits the die, it is a rigid, finished part that is then cut to a specified length. The resulting epoxy matrix composites have excellent impact, flexural, compressive strength characteristics, will not rust or crack and have a long life cycle. These stiff, high strength, low weight parts offer protection against corrosion, high dielectric strength, with easy machinability.

Master Bond epoxy systems are noted for their long working life, low shrinkage upon cure and superior water resistance. Design and material engineers rely on Master Bond to meet demanding application requirements for the electrical, rail, construction, marine, paper making, energy and transportation industries.