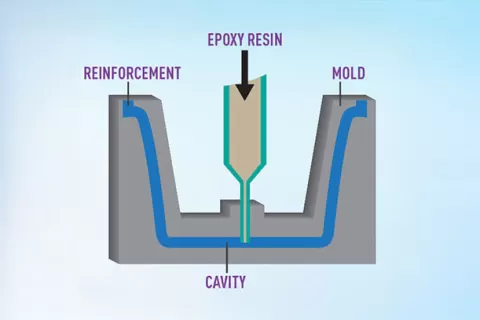

Resin Transfer Molding (RTM)

Resin transfer molding is a closed molding process that offers a highly controlled and efficient method for composite fabrication. A reinforcing material, such as woven roving, is pressed into a mold tool made of polyester, aluminum or mild steel. A second mold is then clamped over first mold, creating a sealed cavity. Then, a liquid epoxy resin is injected into the cavity.

Advantages and Applications

Vacuum assisted resin injection transfer allows the epoxy to displace air fully saturating reinforcing fiber matrices. It is an automated, fast, clean, repeatable process that ensures consistent part thickness and short cycle times. The result is water tight composite parts featuring high strength to weight ratio and good surface finishes. Master Bond provides a range of products specifically formulated for RTM processes, with the right viscosity, gel time, and cure temperature to meet the unique needs of this advanced manufacturing technique.

RTM is widely used in industries requiring high-performance, complex parts with precise specifications. Its applications include automotive and aerospace components, structural and electrical enclosures, and marine systems.