Lid Sealing of Electronic Packages

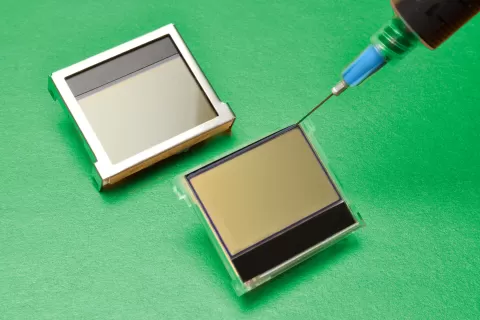

Electronic packages are the protective housings for sensitive electronic components, shielding them from environmental threats and ensuring their long-term performance. A critical aspect of this protection is effective lid sealing, which safeguards delicate circuitry from common dangers such as moisture ingress, harmful contaminants, and the stresses of thermal cycling. While traditional methods like seam welding, soldering, or glass attachment have historically been employed, they often present challenges such as high processing temperatures that can damage sensitive components, potential for metal particle contamination, or limitations in design flexibility. Master Bond's advanced adhesive solutions offer a superior and versatile alternative, providing robust, reliable, and cost-effective lid sealing for a wide array of electronic applications.

Key Performance Properties

Selecting the ideal adhesive for effective lid sealing hinges critically on its performance properties to ensure long-term reliability of the electronic package. Key considerations include the operating temperature range the adhesive can withstand, ensuring it maintains integrity across the device's operational spectrum, and its bond strength to securely seal the lid under various mechanical stresses. Depending on the application, flexibility may also be crucial to accommodate differences in coefficients of thermal expansion between materials, preventing stress-induced failures. Furthermore, the adhesive must offer robust environmental resistance to common threats like moisture, humidity, and aggressive chemicals, preserving the sensitive internal components. For certain high-power applications, the adhesive's thermal conductivity also becomes a vital property, facilitating efficient heat dissipation away from critical components and preventing overheating.

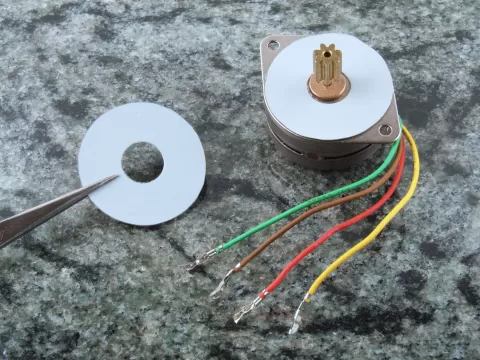

Electrically insulative epoxy paste and B-staged preform adhesives provide effective alternatives in lid sealing applications. They also offer low temperature processing and avoidance of metal particle contamination. These compounds feature high bond strength, thermal stability and superior protection against moisture. Preform systems cure rapidly at moderate elevated temperatures, have controllable flow and long storage stability.

Most Popular Lid Sealing Epoxies