Adhesives for the Assembly of Electronic Devices

Formulations are available to meet the evolving needs of the electronic industry. View the interactive summary of adhesives for electronic applications. Specific grades are available for:

Microwave and RF Adhesives

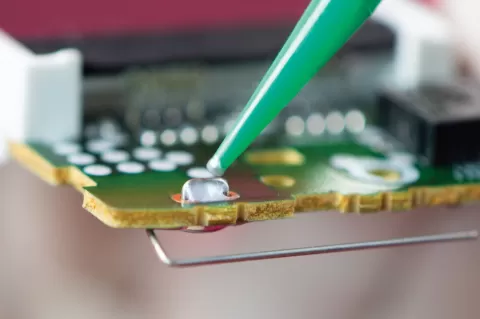

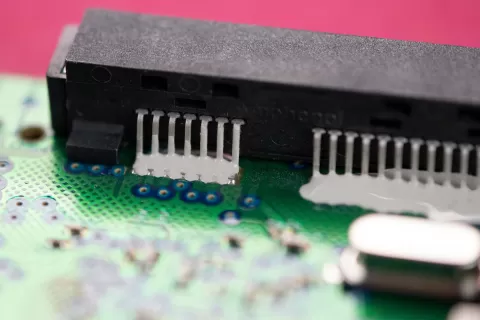

Printed Circuit Board Adhesives

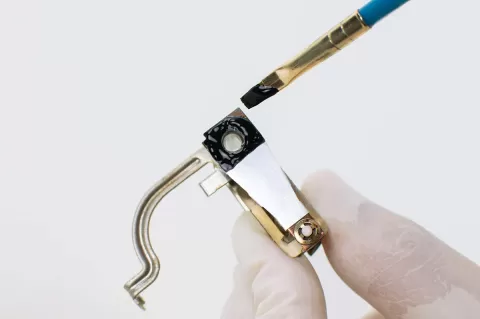

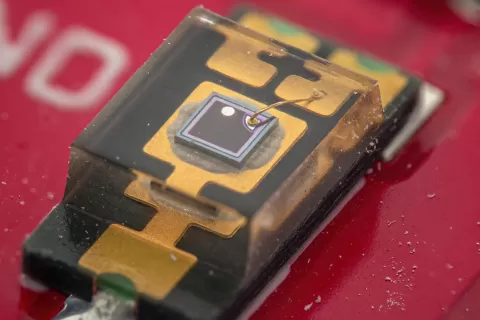

Semiconductor Adhesives

Products include:

Conformal Coatings

Die Attach Adhesives

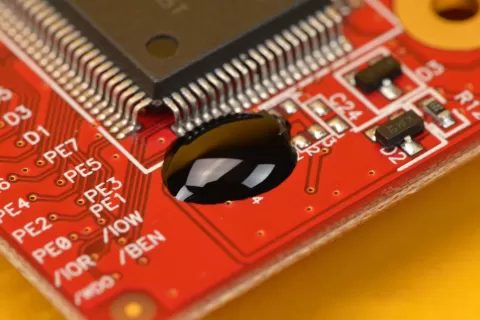

Glob Tops

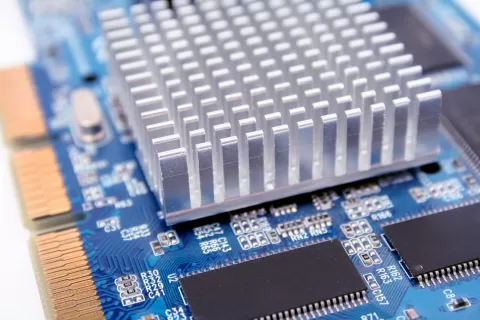

Heat Sink Attachment

Lid Sealing

Surface Mount Adhesives

Underfill Encapsulants

Master Bond Electronic Grade Systems Feature Exceptional Performance Properties

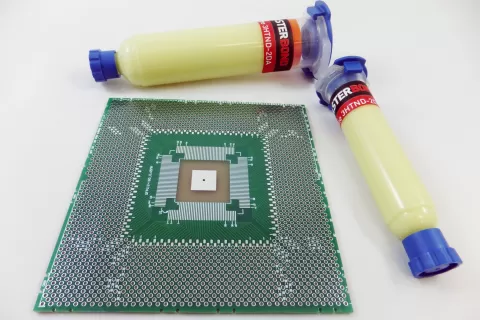

Products are easy to apply and available for use in convenient applicators (including premixed and frozen syringes for two component epoxy systems). Properties of specific grades include:

- High bond strength to similar and dissimilar substrates

- Low stress

- High/low temperature serviceability

- Fast cures

- Resistance to water and many chemicals

- Low coefficient of thermal expansion

Silicone Systems Offer Excellent Protection from Mechanical Stress and Temperature Fluctuations

One and two component electronics grade MasterSil® possess high thermal stability, low moduli of elasticity, superior dielectric properties. Other beneficial characteristics of select silicone compounds are as follows:

- Low shrinkage

- Thermal and electrical conductivity

- Low outgassing

- Chemical inertness

- Low moisture absorption

- Vibration damping

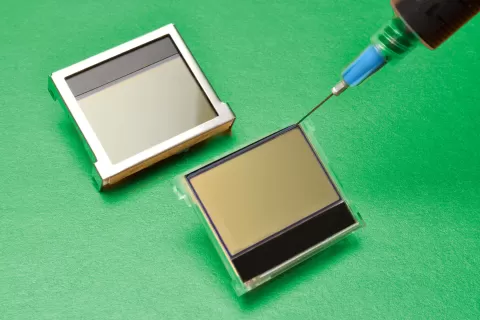

No mix UV/visible LIght Curing Compounds for Protection of Electronic Parts

Rapid curing single part solvent free products feature superior bond strength, environmental resistance for electronic assembly applications. Low viscosity compounds for conformal coating and higher viscosity compounds for glob top applications are engineered to resist abrasion, moisture, vibration and thermal cycling exposure.

Master Bond is a member of the International Microelectronics and Packaging Society.

Master Bond is a member of the International Microelectronics and Packaging Society.

Master Bond is a member of MEPTEC: Microelectronics Packaging & Test Engineering Council.

Master Bond is a member of MEPTEC: Microelectronics Packaging & Test Engineering Council.

Master Bond is a member of the Surface Mount Technology Association.

Master Bond is a member of the Surface Mount Technology Association.

Why Choose Master Bond

Made to Order

All products are made to order, ensuring optimal performance and extended shelf life. Compounds can be customized to meet specific requirements.

Engineer-to-Engineer Consultations

Our expert engineers provide personalized guidance to ensure you select the ideal adhesive and packaging for your specific application.

Flexible Sizing Options

From 1 cc syringes to 5-gallon containers, our products are available in small to large quantities directly from our USA manufacturing facility.

Latest Developments

Find the Right Adhesive for Your Application

With thousands of formulations, our expert engineers provide personalized guidance to ensure you select the ideal material for your specific needs.

Prefer to browse on your own first? Explore our Product Selector.