EP39MHT

Two component, low viscosity, room temperature curing epoxy resin system

Key Features

- Lower exotherm

- Withstands thermal cycling and shock

- Good chemical resistance

- Withstands 1,000 hours 85°C/85% RH

Typical Properties

Viscosity

1,500-3,000 cps

Cure Schedule

75°F in 3-4 days; accelerated by heat curing for 3-4 hours at 150-200°F; optimum cure schedule overnight at 75°F followed by 2-4 hours at 150-200°F.

Hardness

75-85 Shore D

Service Temperature Range

-100°F to +400°F

Elongation

70-90%

Volume Resistivity

>10¹⁴ ohm-cm

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863

1,000 Hours at 85°C/85% RH

Packaging

Case Study

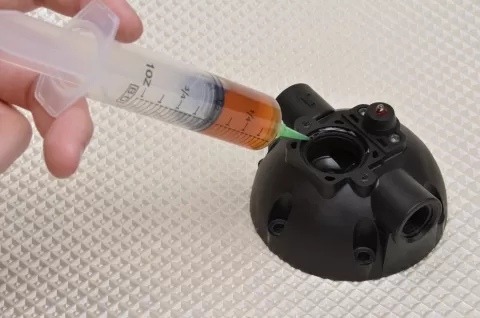

EP39MHT: Utilized to mount magnets in a linear particle accelerator to extract the neutron form factor

Master Bond EP39MHT is a two-component, low-viscosity epoxy resin system that can be cured at room temperature and can withstand rigorous thermal cycling, vibration, and shock. It is suitable for high-performance bonding and sealing applications, suc …