EP30-3LO

Highly versatile, two part epoxy system for bonding, coating, sealing and casting

Key Features

- Superb optical clarity

- Excellent chemical resistance

- Low viscosity and long working life

- High glass transition temperature

- Meets NASA low outgassing specifications

- Withstands 1,000 hours 85°C/85% RH

Typical Properties

Viscosity

2,000-5,000 cps

Cure Schedule

1-2 hours at 170°F followed by 2-3 hours at 300°F

Hardness

80-90 Shore D

Service Temperature Range

-80°F to +450°F

Glass Transition Temperature (Tg)

170-175°C

Volume Resistivity

>10¹⁵ ohm-cm

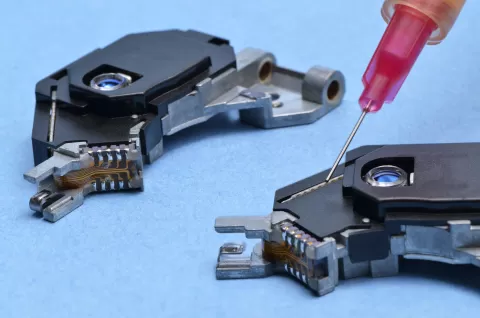

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ASTM E595 Compliant

1,000 Hours at 85°C/85% RH

Meets EU Directive 2015/863