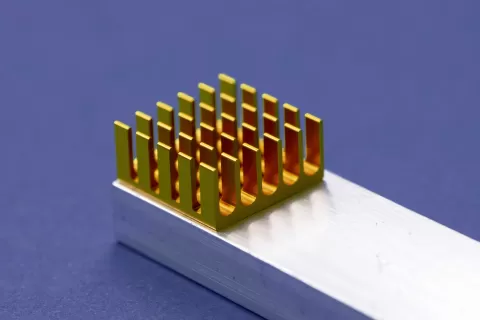

Supreme 46HT-1AO

Two part, thermally conductive, electrically insulative epoxy for bonding and sealing featuring outstanding heat resistance; requires oven curing

Key Features

- Combines toughness and high Tg

- Meets NASA low outgassing specifications

- Withstands 1,000 hours 85°C/85% RH

- Excellent physical properties and dimensional stability

Typical Properties

Viscosity

75,000-150,000 cps

Cure Schedule

2 hours at 300°F, followed by 3-4 hours at 350-400°F.

Hardness

85-95 Shore D

Service Temperature Range

-100°F to +550°F

Dielectric Strength

450 volts/mil

Tensile Modulus

600,000-650,000 psi

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863

1,000 Hours at 85°C/85% RH

ASTM E595 Compliant