MasterSil 151Med Black

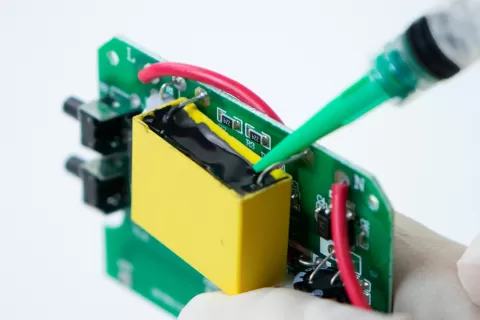

Two component, biocompatible silicone compound for bonding, potting and encapsulation

Key Features

- Low viscosity

- Long open time

- Optically opaque

- Passes ISO 10993-5 for cytotoxicity

Typical Properties

Viscosity

Part A: 2,000-4,000 cps, Part B: 50-150 cps

Cure Schedule

75°F: 24-48 hours; 200°F: 1-2 hours

Hardness

40-50 Shore A

Service Temperature Range

-65°F to +400°F

Dielectric Strength

450 volts/mil

Volume Resistivity

10¹⁴ ohm-cm

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ISO 10993-5 for Cytotoxicity

Meets EU Directive 2015/863

Packaging