UV Curable Systems

Master Bond fast curing, single component UV curable adhesives, sealants, coatings, potting and encapsulation compounds speed productivity and efficiency. They offer excellent adhesion to glass, metals, ceramics, rubber and most plastics. These one part products require no mixing and eliminate waste. Learn more:

UV Adhesives

UV Potting Compounds

Dual (Heat/UV) Cure Systems

Scratch Resistant Coatings

UV Curing Form-In-Place and Cure-in-Place Gaskets

Advantages of Master Bond UV Curable Compounds

- Extremely fast processing time

- Formulated in rigid, semi-flexible and flexible grades

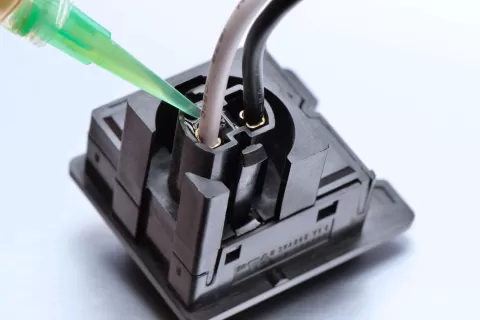

- Available in syringe applicators

- Environmentally safe, no emittance of volatiles or vapors

- Prolonged storage at room temperatures

Features and Properties of UV Curing Systems

As with all products in the Master Bond family, specific grades vary in viscosity, hardness, thermal and electrical properties, but can be customized to fit your application needs.

Free radical and cationic UV curing systems are available for use. They contain a variety of oligomers, monomers, additives and photoinitiators. These liquid blends polymerize when exposed to the proper wavelength/intensity of UV light. In many cases cure speed is in seconds to several minutes and the adhesive can be employed for exact positioning. These cure on demand formulations require no heat and shorten customer lead times, improving their competitiveness/profitability in the marketplace.

From disk drives to semiconductor manufacturing to automotive electronics to displays to printed circuit boards our comprehensive line of UV curing epoxies, acrylates, urethanes are leading the way in reducing labor/assembly costs. These products can be conveniently dispensed manually/automatically and require little manufacturing space. Select systems exhibit excellent thermal stability, low shrinkage, optical clarity, resistance to thermal cycling, chemicals, moisture, solvents while meeting safety, health and ecological concerns. Special grades have secondary heat cure mechanisms for shadowed out areas and nanosilica fillers for enhanced performance.

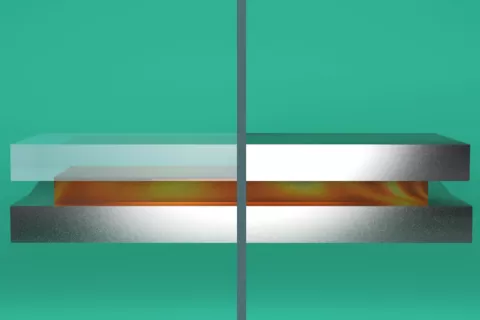

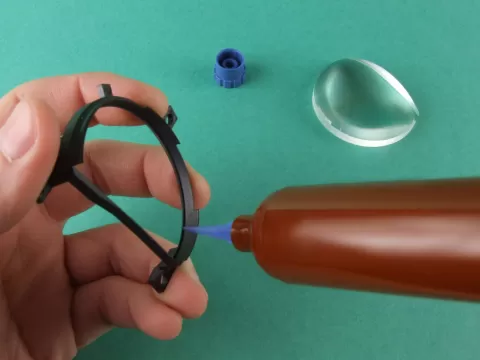

Rigid UV and Dual Curing Adhesives

Rigid light curing products cure on demand for precise alignment between substrates requiring exact positioning. They feature good wetting properties and high optical clarity. UV curable hardcoats guard clear plastic substrates such as polycarbonates, polymethylmethacrylates from scratching, common chemicals, staining. They are employed on automotive headlights, touchscreen displays and safety glasses. Nanosilica filled UV curing and dual UV/heat cure products have been developed for advanced performance requirements. It is important to note that dual cure products will cure effectively in "shadowed out" areas with moderate heat exposure. They have successfully passed NASA low outgassing specifications and can cure in thicknesses of a few microns to about 1/8 inch.

Fluorescent UV Curable Compounds

Specific grades containing a blue fluorescing agent can be employed to improve quality control. Cured UV curing products can be inspected using a "black light". They are often used for positive identification/authentication. This can be addressed manually. The blue fluorescing agent contrasts well with multiple substrate/components and enables easy inspection even for deep curing materials. A limited quantity of the fluorescent agent is added and performance/processing characteristics including depth of cure are unaffected by their addition. Electro optic automatic devices have enabled increased design complexity and recognition of voids that can be harmful in bonding/conformal coating applications. The "glow" from the fluorescence of UV cured systems has been essential in enhancement of processing speeds, in ensuring reliability, eliminating any defects while meeting target specifications. Upon request, blue fluorescing agents can be incorporated into other Master Bond UV cure products.

Some of Our Most Popular UV Curable Products

Why Choose Master Bond

Made to Order

All products are made to order, ensuring optimal performance and extended shelf life. Compounds can be customized to meet specific requirements.

Engineer-to-Engineer Consultations

Our expert engineers provide personalized guidance to ensure you select the ideal adhesive and packaging for your specific application.

Flexible Sizing Options

From 1 cc syringes to 5-gallon containers, our products are available in small to large quantities directly from our USA manufacturing facility.

Find the Right Adhesive for Your Application

With thousands of formulations, our expert engineers provide personalized guidance to ensure you select the ideal material for your specific needs.

Prefer to browse on your own first? Explore our Product Selector.