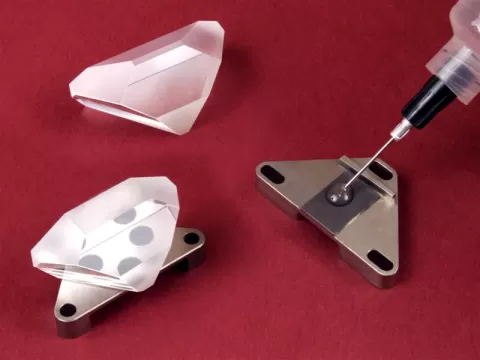

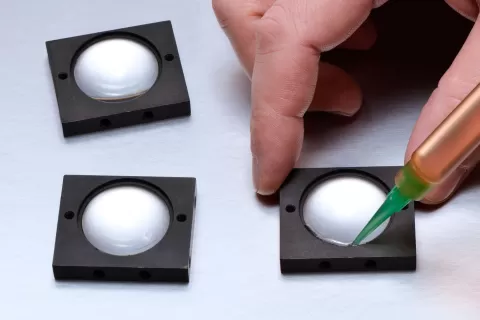

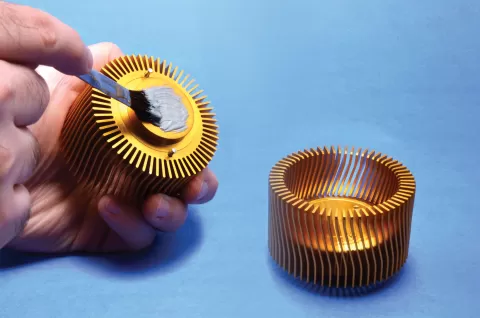

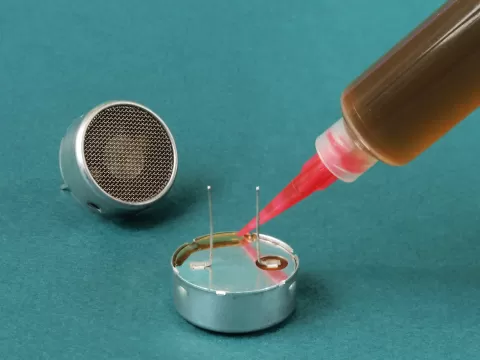

Bonding

Master Bond formulates a wide variety of one and two component industrial adhesive systems. Each compound is designed to meet specific performance requirements and is available for use in small to large sizes. Our line of formulations consists of epoxies, polyurethanes, silicones, polysulfides, cyanoacrylates and UV cure systems.

Bonding Substrates

Master Bond adhesive systems provide exceptional bonding strength to many similar and dissimilar substrates. Learn more about our adhesives for the following materials:

Ceramics

Composites

Dissimilar Substrates

Glass

Metals

Plastics

Polyolefins

Rubbers

Silicone Elastomers

Key Benefits of Master Bond Adhesives

Our compounds utilize the most advanced polymeric materials and offer:

- Widest selection of formulations—over 3,000 grades

- Convenient cure schedules

- Advanced packaging for easy application

- Highest quality

- Latest technology

Learn more about our one and two component structural adhesives.

Performance Properties of Master Bond Adhesives

Our adhesives vary in viscosity, cure speed, mechanical, optical, electrical and thermal properties. Specific grades offer:

- High bond strength to a wide variety of surfaces

- Resistance to moisture and chemicals

- Exceptional durability

- Resistance to vibration, impact and shock

- High and low temperature resistance

Special formulations are available to meet strict industry standards including:

- NASA low outgassing specifications

- USP Class VI certification

- UL 94V-0 flame retardancy

- FDA CFR 175.300 food grade testing requirements

- Halogen free

Learn more about how surface wetting impacts adhesive bond strength.

Our Most Popular Adhesive Formulations

Latest Developments

Find the Right Adhesive for Your Application

With thousands of formulations, our expert engineers provide personalized guidance to ensure you select the ideal material for your specific needs.

Prefer to browse on your own first? Explore our Product Selector.