Aerospace and Aviation Certifications

At Master Bond, we recognize that aerospace adhesives must meet the most demanding safety and performance standards. That’s why a selection of our grades are formulated and tested to comply with key industry certifications of compliance required in critical aerospace environments. Select adhesives meet the following standards: NASA low outgassing, FAR 25.853(a) Flame Retardancy, Airbus Testing for Vertical Burn, Smoke, & Toxicity, and Boeing Testing for Smoke Emission & Toxic Gas Generation.

NASA Low Outgassing

FAR 25.853(a) for Flame Retardancy

Airbus Testing for Vertical Burn, Smoke & Toxicity

Boeing Testing for Smoke Emission & Toxic Gas Generation

Properties of Master Bond's Adhesives Meeting Aerospace and Aviation Certifications

Master Bond’s adhesives are tailored to meet diverse performance requirements:

- Thermal: Withstand extreme high and low service temperatures.

- Electrical: Offer insulating, conductive, or static-dissipative properties.

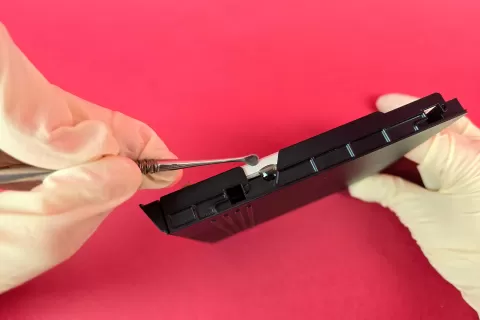

- Mechanical: Provide strong adhesion, toughness, and vibration resistance.

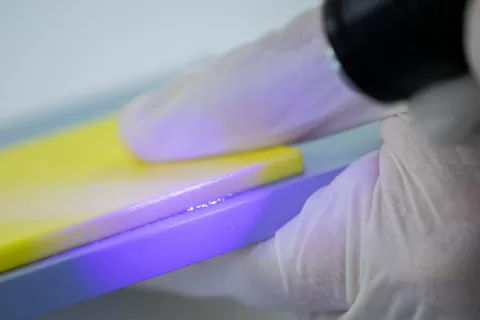

- Optical: Available in transparent, UV-resistant, and light-stable grades.

Additionally, adhesives differ in:

- Viscosity – from thin, flowable grades to paste consistency.

- Curing – room temperature, heat-curable, or dual-cure systems.

- Processing/Handling – adjustable work life, pot life, and application methods.

Depending on the specific aerospace environment and operational demands, Master Bond will recommend the most suitable adhesive system. This ensures that every solution balances compliance, performance, and processing efficiency.

Latest Developments

Find the Right Adhesive for Your Application

With thousands of formulations, our expert engineers provide personalized guidance to ensure you select the ideal material for your specific needs.

Prefer to browse on your own first? Explore our Product Selector.