MIL Spec Approved One Part Silicones

Master Bond has developed one part silicone systems that meet the requirements of the following military specifications: MIL-A-46146 and MIL-A-46146A Type 1. These products require no mixing and cure at room temperature. They feature superior electrical insulation properties and exceptional durability.

Military Specification MIL-A-46146 outlines the requirements for non-corrosive, room temperature-vulcanizing (RTV) silicone adhesive-sealants.

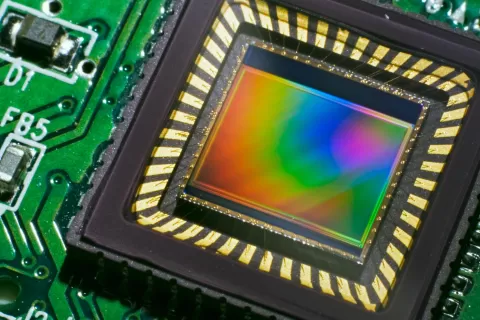

Within the MIL-A-46146 specification, different "Types" are designated based on the material's consistency and flow properties. Type 1 refers to products that exhibit a "soft spreadable thixotropic paste" consistency. This non-sagging nature makes them ideal for applications where the sealant needs to maintain its shape, such as vertical or overhead installations, or for precise application around delicate components. These paste-like compounds are highly suitable for aerospace and electronics, providing robust bonding and protection for critical assemblies.

One Component Silicones Meeting MIL-A-46146 and MIL-A-46146A Type 1 Specs