Vidéo

Max Year in Review

Five! Four! Three! Two! One! Max marks the end of 2013 in his latest video by counting down the year’s most exciting and innovative products including a light curing compound, a B-staged adhesive film and more.

Featured Products Covered in this Video

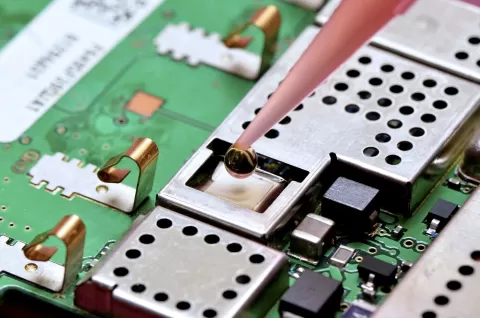

Image

One part, no mix, fast curing compound. Tack free cure. High bond strength to a wide range of substrates. Solvent free formulation. Withstands 1,000 hours 85°C/85% RH. Serviceable from -60°F to +250°F.

Image

Two part, room temperature curing, epoxy gel compound for sealing and encapsulation. Optically clear, soft and dimensionally stable. Ideal for retrievability. Two to one mix ratio by weight or volume. Low exotherm. Long working life. Low viscosity system. Unsurpassed thermal cycling and mechanical shock resistance. Used in conjunction with sensitive electronic and optical components. Serviceable from -100°F to +200°F.

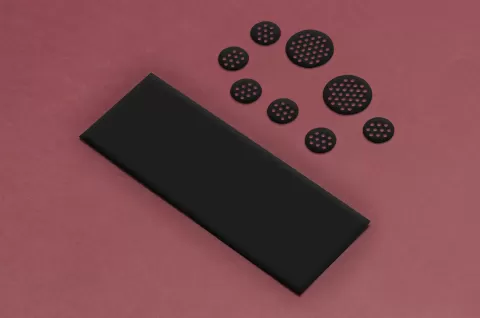

Image

B-staged film adhesive/sealant. Outstanding thermal cycling capabilities and structural properties. Offers superior toughness and flexibility. Excellent strength retention at elevated temperatures. Thermally conductive/electrically insulative. Provides uniform bond line thickness. Serviceable from -100°F to +500°F. Preforms are available.

Image

Aqueous based sodium silicate system. One component, silver filled formulation. Highly effective moisture barrier. Bonds well to a wide variety of substrates. Temperature resistance up to 700°F. Excellent shielding effectiveness. Simple, safe handling.

Image

Paste consistency. Convenient one to one mix ratio. Elongation 400-500%. Highly water resistant. Self priming feature. Meets USP Class VI and ISO 10993-5 requirements. Superior thermal stability. Resists vibration, shock. Serviceable from -65°F to +400°F.