UL Certifications

UL Flammability and Safety Standards for Epoxies

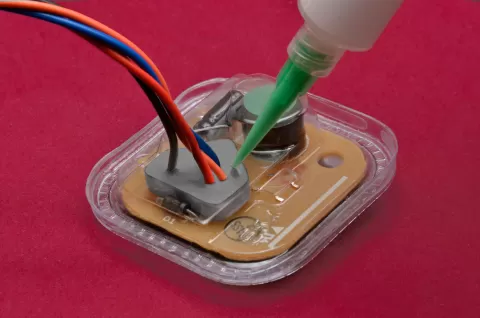

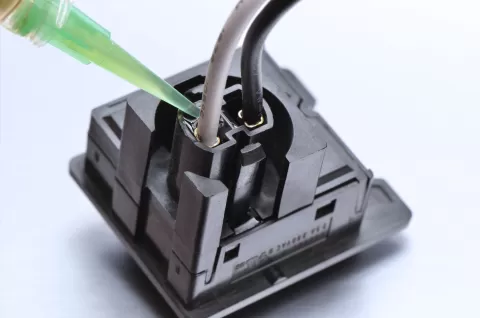

Epoxies used in electrical, electronic, and industrial assemblies are often required to meet rigorous safety standards that address fire resistance, thermal performance, and hazardous environment suitability. Among the most recognized benchmarks are UL94V-0 and UL94V-1, which evaluate a material’s ability to self-extinguish after flame exposure. UL94V-0 is the most stringent, requiring samples to stop burning within 10 seconds without dripping flaming particles, while UL94V-1 permits up to 30 seconds of burning with limited dripping. These classifications help ensure adhesives and encapsulants reduce the risk of flame spread in sensitive applications.

Thermal and Hazardous Environment Testing

In addition to flammability, UL746A testing assesses the long-term thermal aging and electrical properties of polymeric materials when exposed to elevated temperatures. This standard is critical for evaluating the durability of epoxies used in demanding electrical insulation or structural bonding applications. For environments with explosive or flammable gases, UL1203 provides further assurance by certifying that materials, including epoxy coatings and sealants, are safe for use in hazardous locations. Together, these UL standards demonstrate that epoxy systems are engineered not only for performance but also for compliance with the highest safety and reliability requirements across industries.

UL 94V-0

UL 746A High Amp Arc Ignition Resistance

UL 1203

Latest Developments

Find the Right Adhesive for Your Application

With thousands of formulations, our expert engineers provide personalized guidance to ensure you select the ideal material for your specific needs.

Prefer to browse on your own first? Explore our Product Selector.