Testing Epoxies for Resistance to Sulfuric Acid

Many Master Bond epoxy systems are formulated with superior chemical resistance. In the lab we continually test our materials by exposing them to specific chemicals over a long period of time. We do this by immersing a sample in a chemical and measuring its change in weight over time. A significant loss or gain in weight would indicate a decreased ability of a material to stand up to chemical exposure. These tests allow us to more accurately recommend the right adhesive based on specific application requirements.

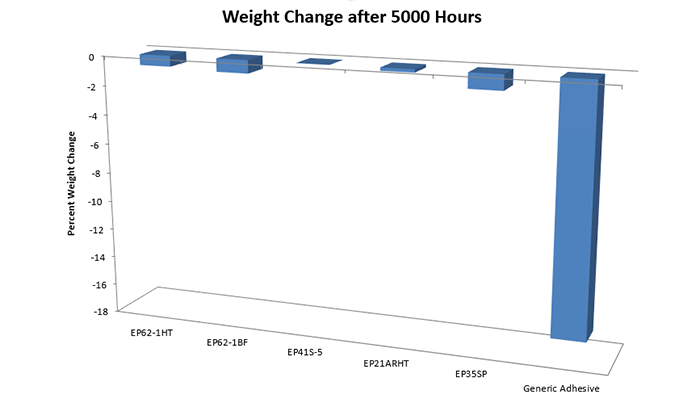

In this experiment, we tested our epoxies for their resistance to sulfuric acid at an independent lab. The compounds we tested were two component epoxy systems with good overall chemical resistance. These include EP62-1HT, EP62-1BF, EP41S-5, EP21ARHT, EP35SP and a generic epoxy adhesive for comparison. A pre-measured casting weighing a few grams of each product was created. Once the cured samples were ready and initial weight was recorded, we submerged them in a 98% solution of sulfuric acid. Then we continued recording monthly weight measurements. Although we plan to carry on with these weight recordings over a longer period of time, below you will see the percentage of weight change after the first 6 months of testing.

To put these numbers into perspective, a change of less than +/-2% can be considered excellent, especially since this test may be more rigorous compared to actual service conditions. It is also worth noting that in the context of a bonded joint or a potted assembly, the exposure to acids might not be as severe or direct, as in the above test conditions.

Change in hardness in epoxies after exposure to sulfuric acid

Additionally, we measured the change in hardness after immersion in sulfuric acid. If there is little to no change in the hardness measurements, it can be concluded that the adhesive performed well and was not impacted by the chemical exposure.

| Epoxy System | Shore D Hardness, Initial | Shore D Hardness, after 5000 Hours |

| EP62-1HT | 91 | 88 |

| EP62-1BF | 90 | 88 |

| EP41S-5 | 90 | 89 |

| EP21ARHT | 90 | 87 |

| EP35SP | 93 | 92 |

| Generic Adhesive | 90 | 70 |

Please note, when choosing an epoxy for an application where the resistance to sulfuric acid is critical, many other factors must be considered in addition to the chemical resistance. Each of the epoxies in the chart above offers a distinct set of performance properties.

Disclaimer: The findings in this article are not meant to be used for specification purposes.

Master Bond Acid Resistant Epoxies