EP126

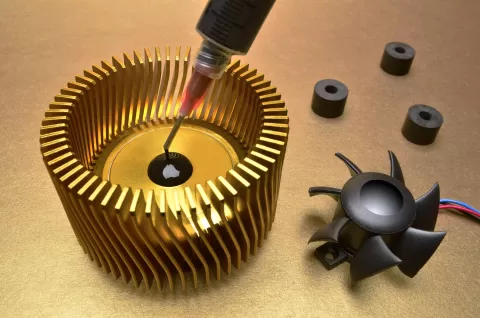

Two part epoxy for bonding and sealing featuring very high temperature resistance

Key Features

- Excellent glass transition temperature

- Noteworthy bonding strength

- Outstanding chemical resistance

- Top notch machineablilty

Typical Properties

Viscosity

250,000-500,000 cps

Cure Schedule

3-4 hours at 300°F or 2-3 hours at 350°F

Service Temperature Range

-80°F to +600°F

Dissipation Factor

0.091 @ 75F; 0.034 @ 500F

Glass Transition Temperature (Tg)

160 to 180°C

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863

Video

EP126: How Do You Mix a Two Part Epoxy When Part B is a Powder?

Watch this demonstration to learn the step by step process of mixing a two part epoxy system, where Part A is a liquid and Part B is a powder. Epoxy system EP126 was used in this video.