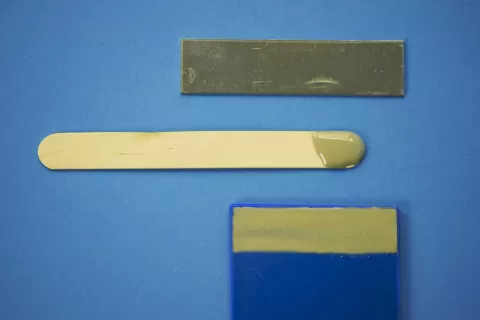

EP33ND

Two component, room temperature curing epoxy for bonding and sealing

Key Features

- Thick paste consistency

- Good machinability

- High temperature resistance

- Demonstrated radiation stability at high radiation dosages

- Withstands 1,000 hours 85°C/85% RH

Typical Properties

Viscosity

Part A: paste, Part B: paste

Cure Schedule

overnight at 75°F followed by a post cure at 150-200°F for 2-3 hours

Hardness

80-90 Shore D

Service Temperature Range

-60°F to +450°F

Tensile Lap Shear Strength

2,200-2,400 psi

Tensile Modulus

400,000-450,000 psi

Immagine