Supreme 11HTND

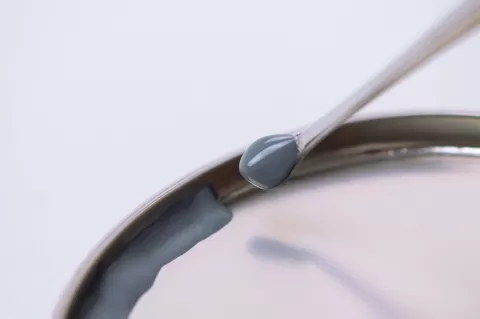

Toughened, two component epoxy for bonding, sealing and coating with paste consistency

Key Features

- Convenient handling

- Excellent toughness

- Withstands thermal cycling

- High bond strength in shear and peel modes

Typical Properties

Viscosity

Part A: paste, Part B: paste

Cure Schedule

overnight at 75°F, followed by 1 hour at 150-200°F

Hardness

75-85 Shore D

Service Temperature Range

-112°F to +400°F

Tensile Lap Shear Strength

3200-3400 psi

Tensile Modulus

300000-350000 psi

Immagine