Curing Properties

Master Bond adhesives, sealants and coatings offer a variety of different curing processes, designed for easy processing and high reliability. Types of processes vary in cure speed, section thickness capabilities and preparation requirements. They include:

By Curing Type

Immagine

Dual Curing

Master Bond’s dual curing compounds cure both upon exposure to UV light and upon exposure to heat. These adhesives, sealants and coatings are applied to assemblies where complete UV curing is either too difficult or impossible to achieve, such as applications with complex geometries and concealed, “shadowed out” areas.

Immagine

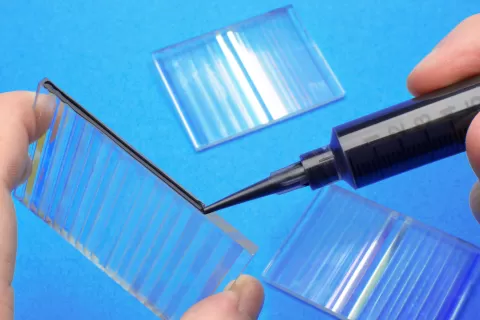

UV Curing

Master Bond fast curing, single component UV curable adhesives, sealants, coatings, potting and encapsulation compounds speed productivity and efficiency. They offer excellent adhesion to glass, metals, ceramics, rubber and most plastics. These one part products require no mixing and eliminate waste.

Immagine

LED Curing

Visible light curable adhesives feature high bond strength, thermal stability, chemical and water resistance and excellent surface cure. These one component compounds are designed to provide safe and rapid cures upon exposure to LED light at ambient temperatures.

By Curing Temperature

Immagine

Heat Curing

One component heat curing epoxy systems can be divided into three categories based on time and temperature of curing: conventional, fast and snap curing systems. Select two part epoxies are engineered to cure only upon exposure to conventional heat.

Immagine

Room Temperature Curing

Room or ambient temperature curing systems offer easy processing and high reliability. These one and two component systems are used in bonding, sealing, coating and potting/encapsulation applications.

Immagine

Low Temperature Heat Curing

Low temperature heat curing one part epoxy systems are formulated to cure at temperatures from 175 to 210°F (80° to 100°C).

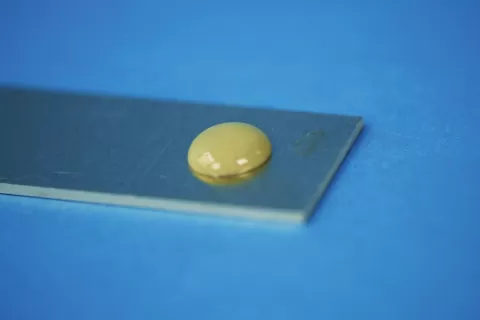

By Curing Speed

Immagine

Fast Curing

Fast curing adhesives can cure in minutes, or even seconds, which can improve assembly time and costs. Fast cure adhesives are available as one and two part formulations and come in a range of different chemistries.

Immagine

Long Working Life

The working life of a two-part epoxy system is the time frame after mixing that the operator can properly dispense and handle the compound before it sets up and is considered no longer workable.

Master Bond can custom formulate a product with a specific curing technique in order to maximize the efficiency of any individual application.

Latest Developments

Why Choose Master Bond

- Personalized technical support from expert engineers

- Adhesives that meet the most demanding industry standards

- Performance and reliability proven by hundreds of publications in peer-reviewed scientific journals

- Freshly made-to-order for maximum shelf life

- Direct from our USA manufacturing facility