Video

Webinar: How to Select the Right Adhesive for Electronic Applications

Watch this webinar for a practical discussion on choosing an adhesive, coating or potting compound for challenging electronic applications. Learn how to navigate the selection process while keeping in mind service conditions, desired properties and processing constraints. Find out more about electronic device applications that span a wide variety of industries, including medical and opto-electronics, oil and gas, aerospace and automotive. Information is included on 6 real life, published case studies where Master Bond adhesives were successfully used and the reasons behind choosing those specific products.

Featured Products in this Video

Immagine

Low viscosity, two part epoxy with outstanding chemical resistance. Passes USP Class VI biocompatibility tests. Capable of withstanding repeated sterilization cycles including radiation, EtO, chemical sterilants, autoclaving. Serviceable from -60°F to +450°F. Cures at room or elevated temperatures. Available in amber-clear and black colors. Castable in thicknesses up to 2-3 inches.

Immagine

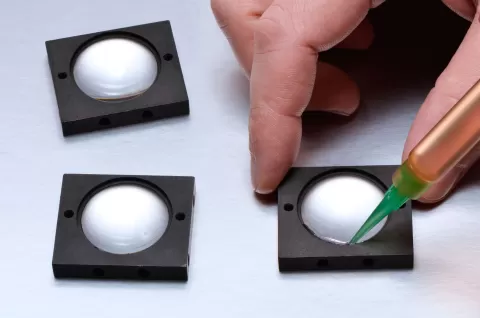

Cryogenically serviceable. NASA low outgassing approved. 100% reactive. Excellent light transmission properties. Outstanding dimensional stability. High tensile and compressive strength. Successfully tested for 1,000 hours 85°C/85% RH. Excellent dielectric properties. Serviceable from 4k to +300°F.

Immagine

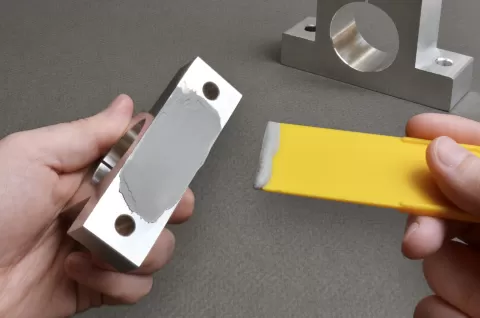

Flexible, low viscosity, thermally conductive epoxy. Meets NASA low outgassing specifications. Superb electrical insulator. Good physical strength. Chemical resistant. Long working life. Withstands 1,000 hours 85°C/85% RH. Guards against mechanical shock and vibration. Excellent flowability. Ideal for potting and casting.

Immagine

One part structural epoxy with high bond strength and excellent adhesion to similar and dissimilar substrates, especially composite materials. Requires oven curing at 250-300°F. NASA low outgassing approved. Serviceable from 4k to +400°F. Tough and durable. 85°C/85% RH resistance.

Immagine

Low viscosity, two component epoxy system. Superior light transmission properties. Rigid curing. Short tack-free time. Can be applied by roller, brush or conventional spraying equipment. Superior chemical resistance. Serviceable from -60°F to +300°F. Successfully tested for 1,000 hours 85°C/85% RH. Guards against wear.