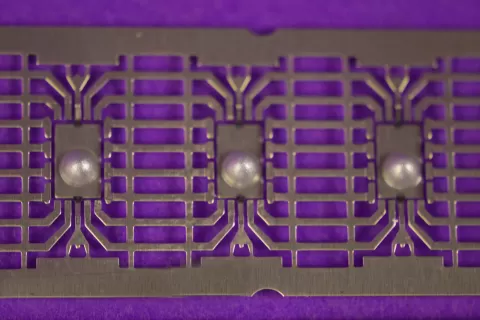

EP3HTSDA-1

One component, highly electrically conductive, die attach epoxy

Key Features

- Low volume resistivity

- Ideal dispensing profile

- Not premixed and frozen

- Very long open time at ambient temperatures

- Cures rapidly at 250-300°F

- Outstanding retention of conductivity

Typical Properties

Viscosity

>400,000 cps

Cure Schedule

250°F for 20-30 minutes, 300°F for 5-10 minutes, plus 1 hour at 250-300°F for optimal properties.

Hardness

75-85 Shore D

Service Temperature Range

-80°F to +400°F

Thermal Conductivity

40-45 BTU•in/(ft²•hr•°F) [5.7-6.5 W/(m•K)]

Volume Resistivity

<0.001 ohm-cm

Bild

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ASTM E595 Compliant

Meets EU Directive 2015/863