EP3HTSDA-2

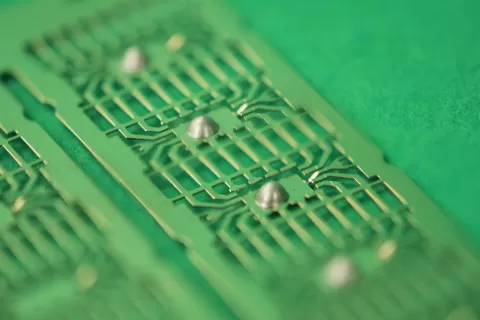

One component epoxy system featuring excellent electrical and thermal conductivity

Key Features

- Low volume and thermal resistivity

- Not premixed and frozen

- Long open time at ambient temperatures

- Cures rapidly at 250-300°F

Typical Properties

Viscosity

>400,000 cps

Cure Schedule

250°F for 20-30 minutes, 300°F for 5-10 minutes, optimum cure schedule is either option above, plus 1 hour at 250-300°F

Hardness

75-85 Shore D

Service Temperature Range

-80°F to +450°F

Thermal Conductivity

45-49 BTU•in/(ft²•hr•°F) [6.5-7 W/(m•K)]

Volume Resistivity

<0.001 ohm-cm

Bild

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ASTM E595 Compliant

Meets EU Directive 2015/863

Video

Product Spotlight: EP3HTSDA-2

Premier die attach epoxy EP3HTSDA-2 features a very impressive thermal conductivity of 40-45 BTU•in/(ft²•hr•°F), substantially higher than other silver conductive epoxies. This video demonstrates how Master Bond EP3HTSDA-2 is dispensed and applied to …