Military Certifications

In demanding military, aerospace, and rugged electronic environments, materials are often exposed to harsh thermal cycling and variable humidity, temperature, and biological conditions. To ensure reliability under such conditions, specific grades of Master Bond adhesives are qualified under MIL-STD-883J for thermal stability and MIL-STD-810G (Method 508.7) for fungus resistance. These tests validate that adhesives maintain their integrity and performance even when subjected to extreme stressors such as prolonged heat and fungal contamination.

MIL-STD-810G for Fungus Resistance

MIL-STD-883J for Thermal Stability

Applications of MIL-STD Adhesives

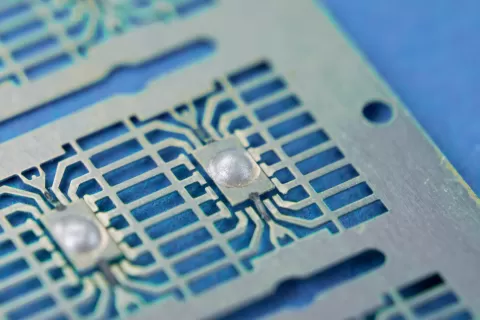

Adhesives that comply with MIL-STD testing criteria are widely used in critical military, aerospace, and electronic applications where performance cannot be compromised. In avionics and satellite assemblies, thermal stability per MIL-STD-883J ensures that adhesives will not degrade or lose mass when exposed to high operating temperatures, thermal cycling, or vacuum conditions. Similarly, fungus-resistant grades qualified under MIL-STD-810G are indispensable for equipment deployed in tropical, marine, or high-humidity environments, where long-term reliability depends on resisting microbial attack. These adhesives are essential for bonding structural components, encapsulating sensitive electronics, sealing housings, and protecting mission-critical systems from environmental stressors.

Beyond compliance with military standards, design engineers often demand adhesives with a combination of mechanical, electrical, and chemical performance attributes tailored to their application. High bond strength, toughness, and resistance to vibration and impact are critical in structural and load-bearing uses. Electrical insulation or conductivity may be required for circuit protection or EMI shielding. Chemical resistance to fuels, lubricants, and cleaning agents is vital in aerospace and defense environments. In many cases, engineers also specify controlled viscosity, cure profiles, and work life to facilitate precise processing and assembly. By combining MIL-STD qualification with these engineered properties, adhesives provide the assurance of both compliance and optimized functionality in the most demanding applications.

Latest Developments

Find the Right Adhesive for Your Application

With thousands of formulations, our expert engineers provide personalized guidance to ensure you select the ideal material for your specific needs.

Prefer to browse on your own first? Explore our Product Selector.