EP125

Two part epoxy for bonding and sealing featuring very high temperature resistance

Key Features

- High glass transition temperature

- Meets NASA low outgassing specifications

- First rate dimensional stability

- Withstands 1,000 hours 85°C/85% RH

Typical Properties

Viscosity

250,000-500,000 cps

Cure Schedule

3-4 hours at 300°F or 2-3 hours at 350°F

Hardness

85-95 Shore D

Service Temperature Range

-80°F to +600°F

Dielectric Constant

3.9

Tensile Lap Shear Strength

2,500-2,700 psi

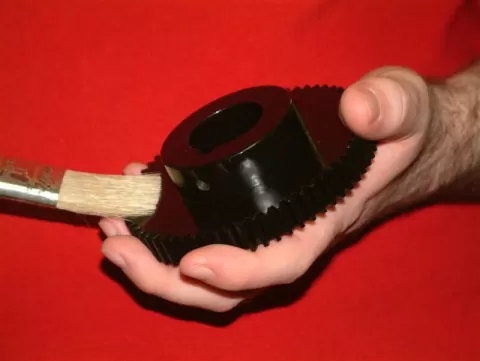

Bild

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ASTM E595 Compliant

Meets EU Directive 2015/863

1,000 Hours at 85°C/85% RH

Packaging