MasterSil 151S

Two part, silver filled, low outgassing silicone for bonding, sealing and coating

Key Features

- Excellent electrical conductivity

- Addition cured type system

- Highly flexible & temperature resistant

- NASA low outgassing

Typical Properties

Viscosity

Part A: paste, Part B: 50-150 cps

Cure Schedule

4-6 hours at 150 to 180°F and 2-3 hours at 190 to 210°F

Hardness

80-90 Shore A

Service Temperature Range

-80°F to +400°F

Elongation

100-150%

Volume Resistivity

0.004 ohm-cm

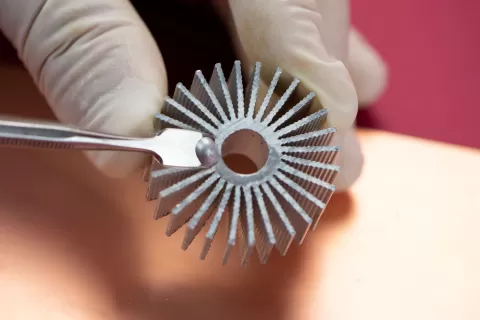

Bild

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ASTM E595 Compliant

Meets EU Directive 2015/863

Packaging