EP29LPSPAO

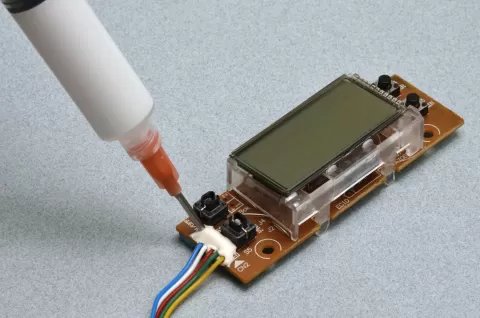

Two component, low viscosity epoxy for bonding, sealing, coating, potting and encapsulation

Key Features

- Thermally conductive, electrically insulative

- Can withstand cryogenic shock

- High dimensional stability

- Vacuum compatible

Typical Properties

Viscosity

4,000-15,000 cps

Cure Schedule

gelling the mixed epoxy at 75°F, followed by alternative lower elevated temperature cure cycles (8-10 hours at 130-150°F) or (5-7 hours at 175°F) or (3-5 hours at 200°F)

Hardness

>75 Shore D

Service Temperature Range

4K to +275°F

Tensile Lap Shear Strength

>1,000 psi

Tensile Modulus

>450,000 psi

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Certifications

Meets EU Directive 2015/863

MIL-STD-810G for Fungus Resistance

Packaging