EP41SMed

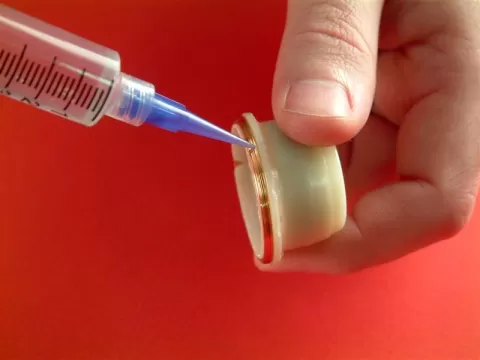

Two part epoxy system for bonding, sealing, coating and potting that meets USP Class VI and ISO 10993-5 for medical applications

Key Features

- Very fast curing; quick handling time

- Highly resistant to chemical sterilants

- Exellent physical strength properties

- Outstanding electrical insulation properties

Typical Properties

Viscosity

Part A: 10,000-15,000 cps, Part B: 3,000 - 5,000 cps

Cure Schedule

24 hours at 75°F, 60-90 minutes at 200°F, optimum cure schedule overnight at 75°F followed by 1-2 hours at 150-200°F

Hardness

>75 Shore D

Service Temperature Range

-60°F to +250°F

Dielectric Constant

3.6

Volume Resistivity

>10¹⁴ ohm-cm

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ISO 10993-5 for Cytotoxicity

Meets EU Directive 2015/863

USP Class VI Medical

Packaging