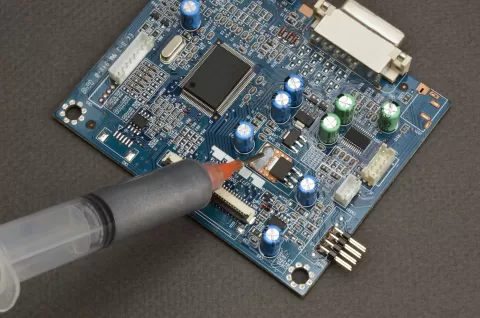

EP79FL

Two component, room temperature curing epoxy for bonding, sealing and coating

Key Features

- Very low volume resistivity

- Outstanding flexibility

- Cost effective

- Silver coated nickel filled system

- Withstands rigorous thermal cycling

- Superior T-peel strength

Typical Properties

Viscosity

flowable

Cure Schedule

overnight at 75°F followed by a heat cure of 2-3 hours at 200°F

Hardness

>50 Shore D

Service Temperature Range

4K to +275°F

Thermal Conductivity

12-15 BTU•in/(ft²•hr•°F) [1.73-2.16 W/(m•K)]

Volume Resistivity

<0.005 ohm-cm

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863

Packaging