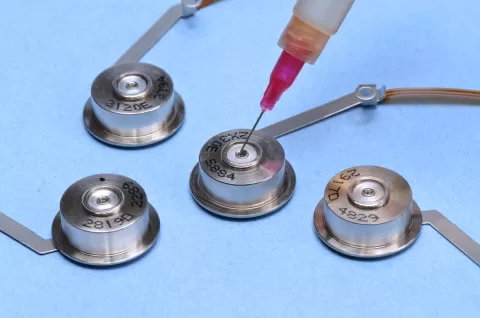

EP38CL

Two component high performance epoxy for bonding, sealing, coating and encapsulation

Key Features

- Superb optical clarity

- Outstanding toughness

- Excellent thermal cycling resistance

- Withstands 1,000 hours 85°C/85% RH

Typical Properties

Viscosity

1,000-4,000 cps

Cure Schedule

75°F for 24-48 hours, 200°F for 1-2 hours

Hardness

75-85 Shore D

Service Temperature Range

-100°F to +250°F

Tensile Modulus

300,000-350,000 psi

Volume Resistivity

>10¹⁴ ohm-cm

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863

1,000 Hours at 85°C/85% RH

Packaging