EP62-1BF

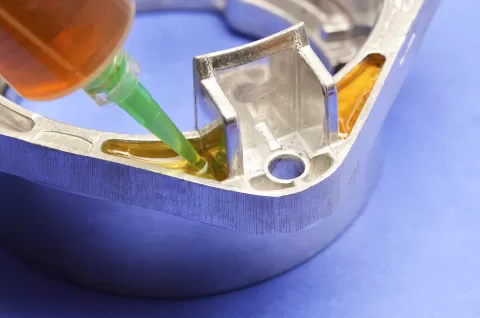

Two component, lower viscosity epoxy system featuring superior chemical resistance

Key Features

- Long open time at room temperature

- Cures well at moderate temperatures

- Can be used for potting small components

- Passes NASA low outgassing

Typical Properties

Viscosity

2,000-5,000 cps

Cure Schedule

6-8 hours at 140-158°F [60-70°C], 60-70 minutes at 176-212°F [80-100°C] or 20-30 minutes at 257°F [125°C]

Hardness

80-90 Shore D

Service Temperature Range

-60°F to +400°F

Dielectric Constant

4.2

Volume Resistivity

>10¹⁴ ohm-cm

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ASTM E595 Compliant

Meets EU Directive 2015/863

Packaging