Supreme 3DM-85

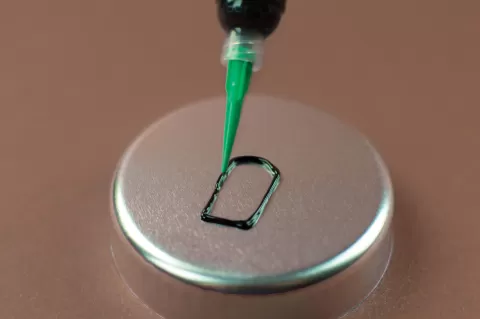

One component, toughened epoxy system for bonding, sealing, and

dam-and-fill encapsulation

Key Features

- No mixing, convenient handling

- Cures at 185°F

- Reliable electrical insulator

- Used as a barrier to block flow

Typical Properties

Viscosity

35,000-95,000 cps

Cure Schedule

Cures at 185°F for 2 to 3 hours

Hardness

75-85 Shore D

Service Temperature Range

-100°F to +350°F

Tensile Strength

2,000-3,000 psi

Volume Resistivity

>10¹⁴ ohm-cm

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863