Thermal Properties of Adhesive Systems

Master Bond offers a number of adhesives, sealants and coatings with exceptional thermal properties. Our product line features the following properties:

Imagen

Cryogenic Serviceability

Master Bond offers a wide range of versatile, high performance epoxy formulations to withstand the severe conditions found in cryogenic environments. These adhesives, sealants and coatings are available as one or two part systems, requiring either ambient or elevated temperature cures.

Imagen

High Temperature Resistance

Master Bond features an extensive line of heat resistant adhesives, sealants, coatings and potting/encapsulation compounds that can withstand temperatures as severe as 600°F and higher. These materials were designed to resist short term and long term exposure to elevated temperatures while maintaining their mechanical and electrical properties.

Imagen

High Tg

The glass transition temperature for a given compound is reported as a single temperature, Tg, which represents the range of temperatures over which a cured epoxy transitions from a glassy, hard state to a more rubbery, softer state.

Imagen

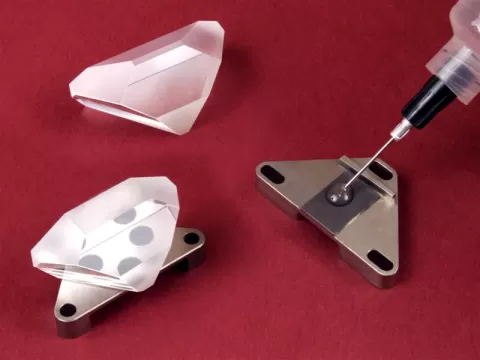

Low CTE

Selecting an adhesive with a low coefficient of thermal expansion (CTE) is one of the approaches to improve the bond strength and stability between dissimilar substrates. Low CTE adhesives mitigate the mismatch in thermal expansion between the substrates being bonded, as well as between the substrates and the adhesive.

Imagen

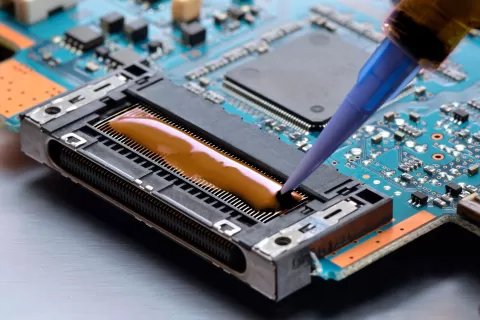

Low Exothermic Epoxy Systems

Polymerization of an epoxy is an exothermic reaction resulting in heat release. Master Bond offers special two component epoxy systems that generate low exotherm even in thick sections. These products avoid premature cures, have lower shrinkage and create less stress than conventional high exothermic systems. This is important in potting/encapsulation and conformal coating applications. Low heat buildup prevents mechanical stresses that can damage electronic devices. Additionally, high viscosity systems are available for gap filling and bonding vertical surfaces, especially for heat sensitive substrates.

Imagen

Low Temperature Serviceability

Adhesive serviceability at cold temperatures presents a number of challenges. Often, adhesives will crack at lower temperatures. Others will debond/delaminate from a substrate material. Epoxy adhesives in particular do very well at low temperatures. They actually increase in bond strength and their physical properties are higher than at room temperatures. In fact many epoxies can be used in cryogenic applications for bonding, sealing, potting/encapsulation. Select silicone systems perform well at -40°C to -50°C. Other special formulations are designed to withstand -100°C. It is important to note that these silicone systems remain highly flexible at low temperatures. Epoxy polysulfides and urethane-modified epoxies are also noted for their serviceability at low temperatures.

Imagen

Thermal Cycling Resistance

Master Bond offers a wide variety of epoxies, silicones, polyurethanes, polysulfides and UV curable formulations designed to withstand thermal cycling. These compounds are also ideal for the bonding, sealing, coating and potting/encapsulating of substrates exhibiting different coefficients of thermal expansion and contraction. Durable and tough, these products exhibit outstanding performance in high and low temperature environments.

Imagen

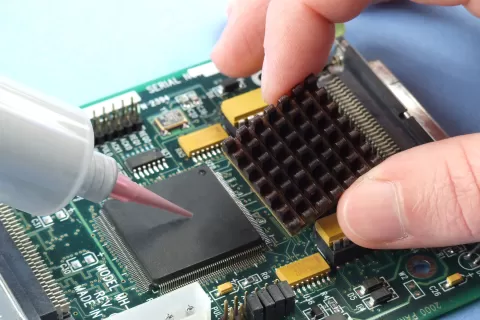

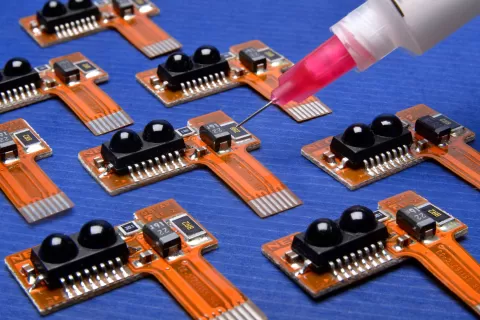

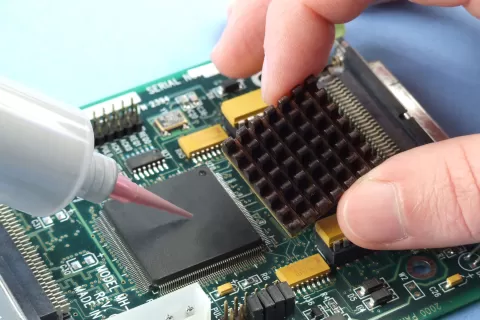

Thermal Conductivity

Master Bond's thermally conductive adhesives offer superior heat dissipation for a wide range of electronic applications. Both one and two component systems are available for use.

Imagen

Thermal Insulation

Inhibiting heat transfer is of crucial importance in many inudustrial bonding and coating applications. Many epoxy and polyurethane systems feature a range of heat insulative properties. These compounds can be used where electrical insulation or isolation is required. They offer high bond strength, low outgassing, thermal stability, excellent corrosion resistance, durability and dimensional stability. Additionally they contain no solvents and are easy to apply in thin layers.

Applications of Polymer Compounds with Advanced Thermal Properties

Master Bond adhesives withstand temperatures as low as 4K and as high as 600°F. They can be used in almost any application that requires resistance to extreme temperatures. Our adhesive systems differ in temperature resistance, thermal cycling resistance, viscosity, flexibility, cure times and other properties. For unusual requirements, we can custom formulate a product that meets your individual design needs.

Latest Developments

Why Choose Master Bond

- Personalized technical support from expert engineers

- Adhesives that meet the most demanding industry standards

- Performance and reliability proven by hundreds of publications in peer-reviewed scientific journals

- Freshly made-to-order for maximum shelf life

- Direct from our USA manufacturing facility