Epoxies with Low Coefficient of Thermal Expansion

Selecting an adhesive with a low coefficient of thermal expansion (CTE) is one of the approaches to improve the bond strength and stability between dissimilar substrates. Low CTE adhesives mitigate the mismatch in thermal expansion between the substrates being bonded, as well as between the substrates and the adhesive.

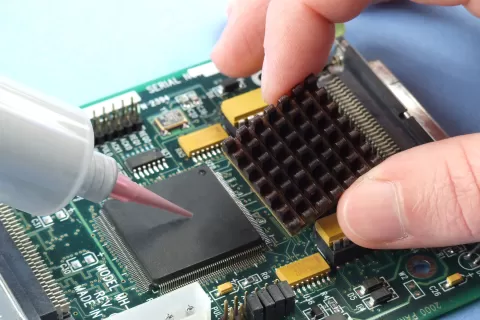

One and two component advanced epoxy systems have been developed for joining dissimilar substrates exposed to thermal/mechanically induced stresses. These dimensionally stable, low shrinkage compounds which are formulated with select fillers offer extra low coefficients of thermal expansion. Products provide the integrity of bonded joints even from high/low temperature exposure. Grades consist of electrically insulative and thermally conductive/electrically isolating systems. They are available for use in a variety of viscosities. NASA low outgassing approved systems meet ASTM E595 requirements for critical aerospace, optical, electronic and specialty OEM needs. Select products have been employed as thermal interface materials to optimize heat transfer and improve device reliability.

CTE Testing Results

| Product | CTE ppm/°C @ 23°C | Tg | Service Temperature Range |

|---|---|---|---|

| EP42HT-2LTE | 9-12 | 60-70°C | 4K to +300°F (4K to +149°C) |

| EP30LTE-2 | 10-13 | 85-95°C | -100°F to +250°F (-73°C to +121°C) |

| EP42HT-3AO | 10-20 | 140-145°C | 4K to +400°F (-269°C to +204°C) |

| EP13LTE | 15-20 | 160°C | -60°F to +500°F (-51°C to +260°C) |

| Common Materials: Typical CTE Range for Comparison | |

|---|---|

| Material | CTE ppm/°C @ 23°C |

| Ceramics | 0 - 10 |

| Metals | 10 - 30 |

| Plastics | 40 - 120 |

| Rubbers | 100 - 300 or higher |

Most Popular Low Coefficient of Thermal Expansion Epoxies