EP112

Two part, heat curing epoxy for potting, encapsulation, coating, sealing and impregnation

Key Features

- Very low viscosity

- Superior electrical insulation heat resistance

- Excellent optical clarity

- Withstands 1,000 hours 85°C/85% RH

Typical Properties

Viscosity

50-200 cps

Cure Schedule

1-2 hours at 200-210°F followed by 3-4 hours at 250°F and then 4-6 hours at 300°F

Hardness

75-90 Shore D

Service Temperature Range

-60°F to +450°F

Refractive Index

1.55

Volume Resistivity

>10¹⁴ ohm-cm

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

1,000 Hours at 85°C/85% RH

Meets EU Directive 2015/863

Case Study

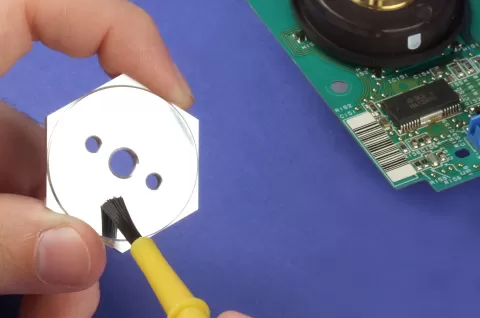

EP112: Utilized to Bond Silicon Wafers to Glass Support Substrates during Microelectronics Fabrication

Master Bond EP112 is an ultra-low-viscosity, electrically insulating, two-component epoxy system ideal for various applications. This two-part case study series presents two use cases for EP112 for microelectronics fabrication processes when used to …