Master Bond EP114 is a two component, nanosilica filled epoxy system for potting, coating and sealing. The addition of the nano particles enhances the dimensional stability and the already exceptionally low shrinkage upon curing. EP114 has a 100 to 80 mix ratio by weight. It has an unusually low viscosity along with a very long open time of 2-4 days. EP114 requires oven curing. A typical cure schedule is 2-3 hours at 250°F followed by 5-8 hours at 300°F with a 2 hour or longer post cure at 350°F, although a number of variations are possible.

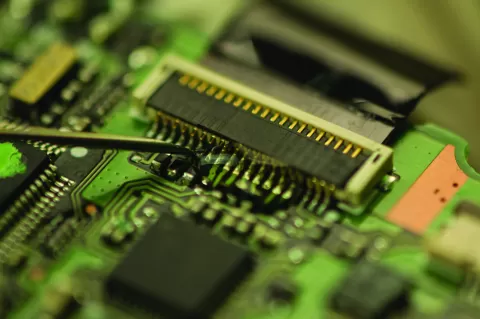

EP114 bonds well to a wide variety of substrates including metals, composites, glass, ceramics and plastics. It is a top tier electrical insulator. Its Tg exceeds 200°C and the service temperature range is -100°F to +550°F. It is highly resistant to water, oils, and fuels. EP114 is optically clear and transmits light very well, especially in the range of 350 to 1600 nanometers. While EP114 is ideally suited for small potting and encapsulation applications, it can also be used for sealing and coating. EP114 should be considered in specialty OEM, electronic, and optical applications where this combination of properties is desirable.

Product Advantages

- Low viscosity

- Very long open time

- First rate electrical insulation properties

- Tested for abrasion resistance per ASTM D4060-14

- Withstands 1,000 hours 85°C/85% RH

- NASA low outgassing approved