Master Bond EP30M3LV-2NV is a low viscosity, two component epoxy system for high performance bonding, sealing and encapsulation. This system is free flowing with a long working life. It has a forgiving 100 to 50 mix ratio by weight. It will cure at ambient temperatures or more rapidly at elevated temperatures. The optimum cure schedule is overnight at 75°F followed by 3-4 hours at 135-165°F. EP30M3LV-2NV is a toughened system that is less rigid and typical of more standard two part epoxies. Also, this system contains an air release agent to limit formation of air bubbles upon mixing.

EP30M3LV-2NV has excellent physical strength properties and bonds well to a wide variety of substrates. These include metals, composites, ceramics, glass, and many rubbers and plastics. Since this epoxy is toughened, it offers outstanding protection from vibration and shock. Additionally it resists rigorous thermal cycling. EP30M3LV-2NV is a superb electrical insulator.

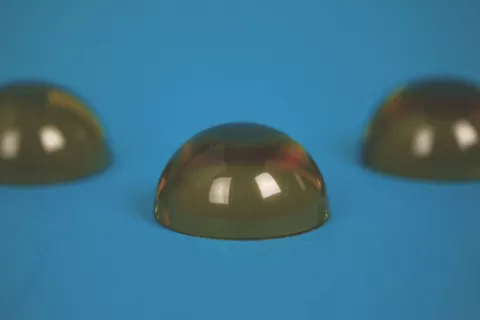

Other noteworthy properties include reasonably good chemical resistance to water, fuels, oils, acids and bases. The service temperature range is -80°F to +250°F. The color of Part A is black and Part B is amber. These properties along with its long open time and low viscosity make it particularly well suited for potting and encapsulation. This system should be considered in electronic, opto-electronic, aerospace, specialty OEM, and other industries, where a first rate system is required.

Product Advantages

- Convenient mix ratio: 2 to 1 by weight

- Low viscosity, long open time

- Contains air release agent

- Resists thermal cycling

- Exceptional electrical insulation