MasterSil 151TC

Two part, room temperature curing, thermally conductive silicone with ultra fine particle filler for bonding and smaller gap filling

Key Features

- High thermal conductivity

- Very good electrical insulator

- High flexibility and temperature resistance

- Meets NASA low outgassing specifications

Typical Properties

Viscosity

30,000-60,000 cps

Cure Schedule

Optimum cure is overnight at 75°F followed by 1-2 hours at 150-200°F.

Hardness

80-90 Shore A

Service Temperature Range

-65°F to +400°F

Dielectric Strength

450 volts/mil

Thermal Conductivity

4.0-5.8 BTU•in/(ft²•hr•°F)

Imagen

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

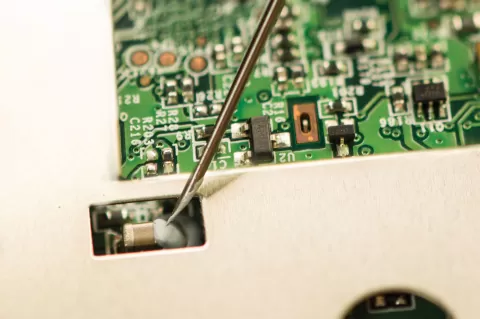

Applications

Certifications

ASTM E595 Compliant

Meets EU Directive 2015/863

Packaging