EP3HTN

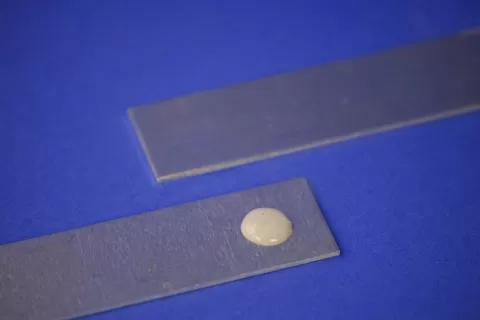

One part, high performance, electrically conductive epoxy

Key Features

- Good electrical conductivity

- Cures rapidly cures at moderately elevated temperatures

- Excellent bonding properties

- Good thermal conductivity

Typical Properties

Viscosity

smooth thixotropic paste

Cure Schedule

Cures readily at 250°F at 45-50 minutes or in just 20-30 minutes at 300°F

Hardness

75-85 Shore D

Service Temperature Range

-60°F to +400°F

Tensile Lap Shear Strength

900-1,100 psi

Volume Resistivity

1-10 ohm-cm

Immagine