EP40TCMed

Two component, thermally conductive, electrically insulative epoxy system for medical device applications

Key Features

- Convenient handling

- Excellent toughness

- Superior bond strength

- Passes ISO 10993-5 specifications

Typical Properties

Viscosity

80,000-100,000 cps

Cure Schedule

overnight at 75°F followed by 3-5 hours at 125°F to 150°F

Hardness

70-80 Shore D

Service Temperature Range

-100°F to +300°F

Elongation

60-70%

Tensile Lap Shear Strength

2,300-2,500 psi

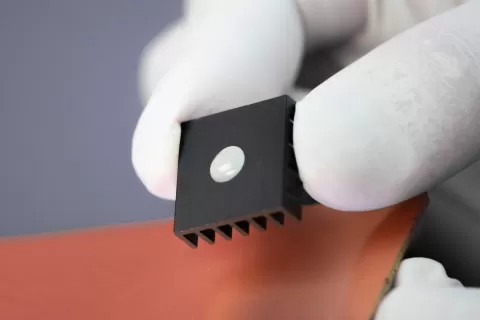

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

ISO 10993-5 for Cytotoxicity

Meets EU Directive 2015/863

Packaging