EP34CA

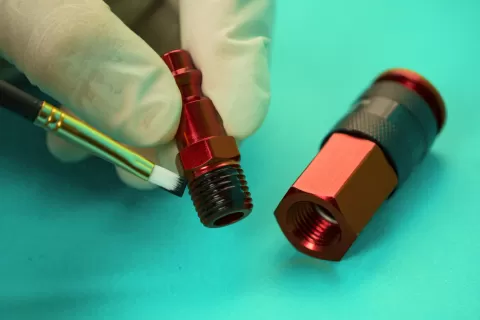

Two component epoxy system for bonding, sealing and coating applications

Key Features

- Very high temperature resistance

- Very long open time

- Good flow properties

- Withstands 1,000 hours 85°C/85% RH

Typical Properties

Viscosity

7,000-20,000 cps

Cure Schedule

gel for 1 hour at 110°C followed by 2-3 hours at 125-150°C

Hardness

80-90 Shore D

Service Temperature Range

-80°F to +500°F

Dielectric Constant

4.1

Glass Transition Temperature (Tg)

200-210°C

Tensile Lap Shear Strength

2,600-2,800 psi

Volume Resistivity

>10¹⁴ ohm-cm

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Certifications

Meets EU Directive 2015/863

1,000 Hours at 85°C/85% RH

Packaging