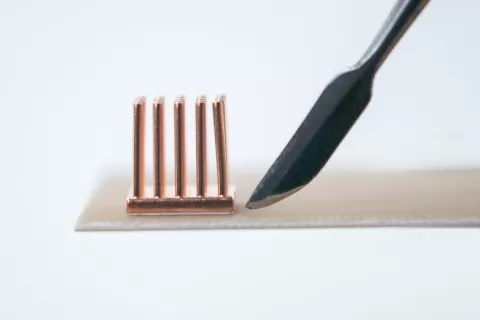

EP54TC

Two part epoxy with high thermal conductivity, electrically insulating, and low thermal resistance for bonding and sealing

Key Features

- Thermal conductivity exceeds 6 W/(m•K)

- Applicable in very thin bond lines

- Low thermal resistance

- Low coefficient of thermal expansion

- Passes NASA low outgassing

Typical Properties

Viscosity

100,000-200,000 cps

Cure Schedule

80°C for 2 hours followed by 2-4 hours at 90-125°C. An alternative cure schedule would be 4-6 hours at 80-90°C.

Hardness

85-95 Shore D

Service Temperature Range

-100°F to +400°F

Dielectric Constant

4.7

Thermal Conductivity

41.6-45.1 BTU•in/(ft²•hr•°F) [6.0-6.5 W/(m•K)]

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863

ASTM E595 Compliant

Packaging