Super Gel 9

Two component urethane modified epoxy gel-like system

Key Features

- Cures to a low Shore A hardness

- Convenient handling

- Room temperature curing

- Relatively easy to remove

Typical Properties

Viscosity

3,000-9,000 cps

Cure Schedule

cures at 75°F, 4-7 days

Hardness

<5 Shore A

Service Temperature Range

-100°F to +200°F

Dielectric Strength

>420 volts/mil

Refractive Index

1.5253

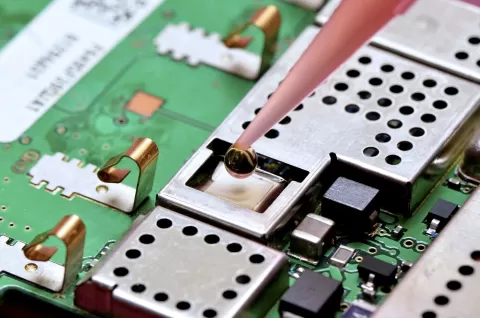

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

Meets EU Directive 2015/863

Packaging