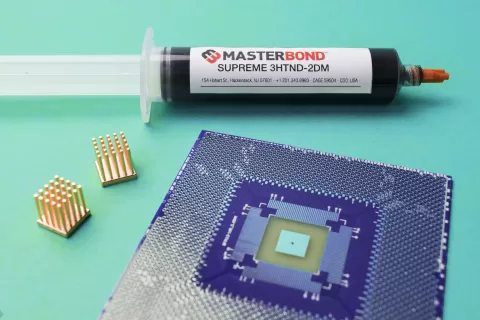

Supreme 3HTND-2DM

One component, toughened epoxy paste for specialty dam-and-fill encapsulation

Key Features

- Used primarily as a barrier to block flow

- Not premixed and frozen

- Stellar electrical insulation properties

- Withstands 1,000 hours 85°C/85% RH

Typical Properties

Viscosity

paste

Cure Schedule

250°F for 20-30 minutes, 300°F for 5-10 minutes

Hardness

80-90 Shore D

Service Temperature Range

-100°F to +400°F

Coefficient of Thermal Expansion

27-30 X 10⁻⁶ in/in/°C

Dielectric Constant

4.6

Dielectric Strength

450 volts/mil

Glass Transition Temperature (Tg)

90°C

Tensile Modulus

250,000-300,000 psi

Thermal Conductivity

10-11 BTU•in/(ft²•hr•°F) [1.44-1.59 W/(m•K)]

Volume Resistivity

>10¹⁴ ohm-cm

Immagine

Discuss with a Specialist

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

(1-2 Business Day Request) Get Technical Data sheet

(Instant Email Delivery) Request Safety Data sheet

(1-2 Business Day Request)

Applications

Certifications

1,000 Hours at 85°C/85% RH

Meets EU Directive 2015/863

ASTM E595 Compliant

Packaging

Video

Product Spotlight: Supreme 3HTND-2DM

Developed for chip-on-board encapsulation applications, Master Bond Supreme 3HTND-2DM is a rapid curing, toughened, one part epoxy system that can be used for dam-and-fill. This video demonstrates the process of dispensing the epoxy paste and creatin …