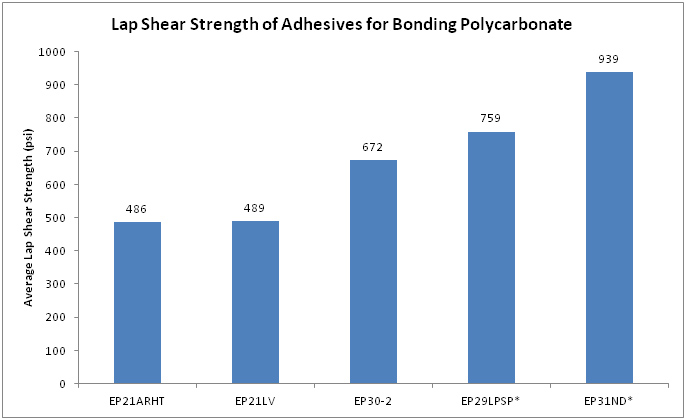

Lap Shear Strength of Adhesives for Bonding Polycarbonate

The graph below displays the lap shear strength of various Master Bond epoxy adhesives for bonding polycarbonate to polycarbonate. Testing was based on ASTM D1002, where two polycarbonate coupons were bonded together and then pulled apart in shear. In order to achieve optimal bond strength, the 4 x 1 x 1/16 inch coupons were roughened, and then cleaned with acetone prior to bonding.

As shown in the graph, EP31ND offers superior bond strength to polycarbonate. However, when choosing the proper adhesive, there are many other factors to consider outside of mechanical strength. Some of these factors include operating temperature range, chemical resistance requirements, as well as handling and processing considerations. For example, if an application requires resistance to some acids / chemicals, EP21ARHT would be desirable. If optical clarity with high light transmission is required, EP30-2 would be a good fit. It should be noted that none of these epoxies cause stress cracking or crazing on polycarbonate.

For more information on Master Bond high strength epoxy adhesives, please contact our technical advisors.

Disclaimer: The findings in this article are not meant to be used for specification purposes.

High Lap Shear Strength Adhesives for Bonding Polycarbonate